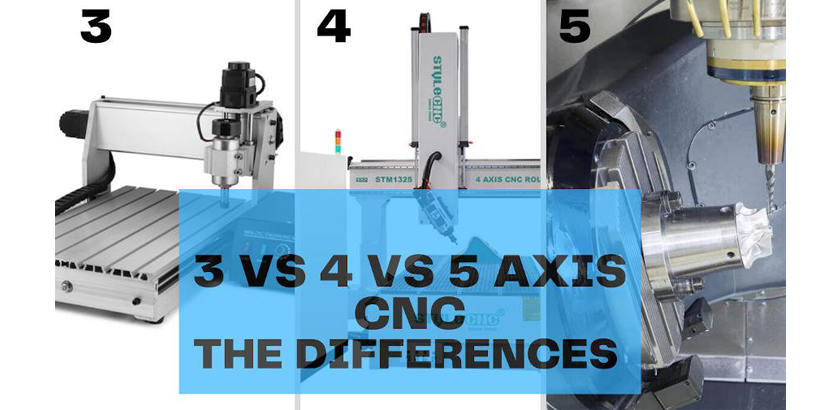

3, 4 and 5-axis CNC Machining, What is the Difference?

Modern CNC milling machines are amazing devices, efficient in making prototypes as well as manufacturing parts quickly and accurately. To do this they should be able to move along numerous axes of travel while preserving dimensional accuracy.

CNC mills are for that reason classified by the variety of axes along which they operate, with 3, 4 and also 5-axis mills being one of the most common. These motions established the part features that can be made and additionally impact manufacturing effectiveness and accuracy. Generally speaking, a lot more degrees of flexibility available, the extra intricate the geometries that can be produced. To see if CNC machining is right for your next task, let’s explore the benefits and also uses of these various kinds.

Table of Contents

What Is A 3-Axis Mill Utilized For?

We make use of 3-axis devices every day for a range of milling operations. They’re excellent for rapid and also effective product elimination and also for making flat or planar surface areas. These geometrical forms are called prismatic, essentially rectilinear, in contrast to more organic forms. Yes, a 3-axis mill can make rounded profiles yet it’s not ideally fit for this task.

3-axis mills are typically utilized to drill and tap holes, however only along the Z-axis. That’s because the spindle goes up and also down as well as can not go into the workpiece from the side. This is a limitation for many parts that need pockets or openings machined on numerous faces, which the 3-axis device can not usually access.

Obviously, this constraint can be conquered if the component is dismounted from the work table and after that repositioned. This serves if there’s nothing else selection, but after that, the work surface should be re-indexed. That means using touch probes to establish a brand-new recommendation point before machining can be rebooted.

This is a slow process and it produces the really real opportunity of developing dimensional mistakes. That’s why taking a part out of its fixture and also rearranging it mid-way via a task is constantly to be avoided preferably.

A 3-axis mill can make round attributes yet only on the X/Y plane. Still, the loved one simpleness of motion is fine for lots of projects that don’t require intricacy and also rather benefit from optimal component throughput as well as process efficiency.

What Are The Advantages Of A 4-Axis CNC Mill?

Adding a fourth axis of activity opens up several new machining opportunities. This is usually achieved by adding rotary movement along the X-axis. Such an extra rotation along X is called the A axis.

The rotary table allows the machinist to place apart on one end and afterwards turn it to access the continuing to besides of the work surface. This avoids the issue of remounting and re-indexing as you would carry a 3-axis mill. Since the component is partially suspended- that is, not touching the surface of the worktable- it’s currently possible to pierce holes or other features that penetrate entirely via a component.

Many substantially, the rotation of the workpiece, while it’s being machined, opens the opportunity to make more complex contours and contours. A part can also be turned as if on a turret, developing spherical and also round profiles. Nevertheless, the 4-axis mill is not maximized for this kind of procedure and so it will certainly be slower than if on a dedicated lathe.

What Are The Conveniences Of A 5-Axis CNC Mill?

Yet an additional degree of freedom can be added, this time around along the Y-axis. Turning around Y is called the B axis.

This is a supporting accessory that gives motion on the An as well as B axes. Taken with each other with the other capabilities of a 3-axis mill, it’s currently possible to make more sophisticated shapes such as helical blades.

There is a limitation to a 3-axis device with a trammel head. For one, a committed 5-axis device is generally a lot extra rigid. That’s because it has to maintain accuracy even while moving in many directions simultaneously. This precision means closer tolerances even for relatively simple parts.

Exactly how Does A CNC Machine Move?

Clearly, we are not discussing the device itself getting up as well as walking away. Rather we’re describing the movement of the cutting device relative to the workpiece, which is what matters right here.

Imagine that you’re dealing with a typical 3-axis CNC mill. The Y-axis is after that the direction perpendicular to you, onward and also back, while the Z-axis is vertical.

In a normal mill, the worktable goes on the X/Y aircraft. The spindle, which holds the cutting tool, travels on the Z-axis. Note likewise that the reducing device revolves in the pin, yet this rotational motion is not considered an axis of activity.

Taken together, the range of these motions specifies a three-dimensional area, a cubic quantity, within which the device executes cutting procedures.

How Many A Lot More Axes Are There?

In the pursuit to make ever before more sophisticated components quickly and with very few configurations, CNC machining facilities are greatly broadening their capacities. Such machines are generally utilized for aerospace, clinical or military applications.

For many items, 5 axes are enough to make feature-rich components to limited resistances. This is what you can expect when you speak to DEK for a free quotation.