4 Tips for Cut a Keyway on a Milling Machine

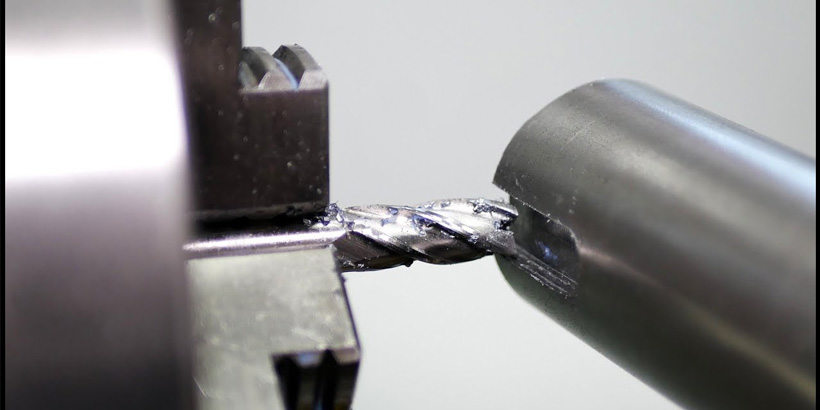

Keyway milling is the procedure of producing a keyway using the milling machine. When you put a wheel on a shaft, the keyway can prevent the sheave from rotating on the shaft. In this article, we’ll introduce what is keyway milling, the fundamentals of essential as well as keyway, methods of milling keyway, as well as cutters of the procedure. The keyway milling procedure can be done either on a specialized keyway milling machine or regular mills. When machining on the keyway milling machine, the work surface is clamped by the fixture, and also the keyway milling cutter is utilized to mill it layer by layer.

Table of Contents

Clamping as well as calibration of the work surface

When clamping the workpiece, not just the stability, as well as reliability of the workpiece, should be guaranteed, yet also the main setting of the clamped parts must not be changed, that is to make sure that the centerline of the keyway accompanies the axis line. Milling keyway clamping techniques typically have the following numerous.

Use parallel-jaw vice

Installment with machine vice is suitable for milling keyway on medium-short and also tiny shafts. When the diameter of the workpiece changes, the center of the part changes in the jaw, which affects the symmetry as well as dimensions of the keyway. However, it is basic, steady as well as suitable for single-piece production. This clamping approach can additionally be made use of for mass production if the external circle of the shaft has actually been ended up.

Use v-shaped structure

The V-shaped structure securing is suitable for crushing the keyway on the long as well as the thick shaft. When the facility of the milling cutter is straightened with the bisector of the angle of the V-shaped iron, the symmetry of the keyway can be ensured.

Use T-slot

Place the shaft on the T-sot of the milling device worktable, and secure the item with the plate directly. When machining long shafts with diameters ranging from 20 mm to 60 mm, they can be directly clamped on the T-slot of the worktable. However, this method is not suitable for tipped shafts and also large-diameter shafts.

Make use of index head

If it is the installation of asymmetrical secret and multi-slot work surface, in order to make the placement of the keyway on the shaft accurately dispersed, the separating head or component with an indexing device is mostly utilized. When the workpiece is clamped by the three-jaw self-centering chuck as well as the back facility of the splitting head, the work surface axis has to be on the axis line between the three-jaw self-centering chuck and also the center, and the placement of the work surface axis will not change with the change of the size. The balance of the keyway on the shaft will certainly not be affected by the adjustment of the workpiece diameter.

The option of keyway milling cutter

In the process of milling keyway, the need of selecting a milling cutter is rigorous, which straight affects the precision and also surface area roughness of the keyway. Generally, the grating open keyway is finished with a disc milling cutter; milling a closed keyway is frequently utilizing an end milling cutter as well as a keyway milling cutter. When crushing with an end mill, a hole with the exact same size as the milling cutter need to be drilled at one end of the groove base, and also the deepness is the groove depth. The option of milling cutting devices will certainly affect surface roughness and also performance. Milling tools suggested for various keyways:

- Shaft keyway for woodruff secret: woodruff vital slot milling cutters

- Square-end keyway: ordinary grating cutter or side milling cutter

- Round-end keyway: end milling cutters

Adjust the cutting position of the milling cutter

In keyway milling, it’s vital to change the associated setting of the cutter as well as parts, and also make the rotation axis of the cutting device is straightened with the axis of the work surface.

Milling of keyway

Layered milling

Layered milling is to reduce the keyway layer by layer, the depth of each operation is only 0.5-1 mm, after that perform the backward and forward crushing with a bigger feed price until it reaches the desired depth. The advantage of this approach is that if the milling cutter is blunt, it just needs to grind completion face, and also the milling cutter diameter is not affected; nevertheless, when processing on the ordinary milling machine, the operation versatility is not good, and the manufacturing performance is lower than the typical cutting.

Broaden milling

Grind the chosen keyway milling cutter till its external diameter is reduced by 0.3-0.5 mm (keep a good cylindricity), when milling, leave 0.5 mm allowance at both ends of the keyway, move the cutter back and forth for milling, as well as then gauge the groove size to figure out the width allocation. Use a milling cutter that adheres to the size of the keyway to continue milling both sides of the keyway to the desired size, and mill to the called for size of the keyway at the very same time.