Guide to Machining Projects

In the manufacturing globe, machining is a process that involves removing excess materials from a work surface. Utilizing power-driven and also hand tools, the supplier forms the product right into its intended style.

Recognized as a metal cutting operation, machining is generally made use of in machining jobs that have metal components. Nevertheless, this procedure is likewise utilized on other products such as plastic, wood, porcelain, as well as rubbers.

As a kind of subtractive manufacturing, modern-day machining is CNC regulated and made use of in lathes, mills, as well as other cutting machines.

Kinds Of Machining Projects

Machining tasks are complex processes that need a knowledgeable machinist and also extensive preparation. Manufacturers supply CNC machining services to produce a ready-to-use part.

Turning

This is a machining procedure executed by the lathe. In the machine shop, the lathe spins the workpiece while the cutting tool remains in one location. This procedure can either be done on the outside or indoor part of the product.

The lathes utilized in these machining jobs can either be by hand run or the automated CNC kinds. The machinist can produce intricate curves using this device in a procedure called 5-axis machining.

Commercially, producers utilize the lathe maker to work on the surface areas of the vehicle’s brake parts. In addition, they are made use of for metal fabricating as well as woodturning in industries such as nuclear power plant, steel plants, paper fabrics, oil, and also mining sectors.

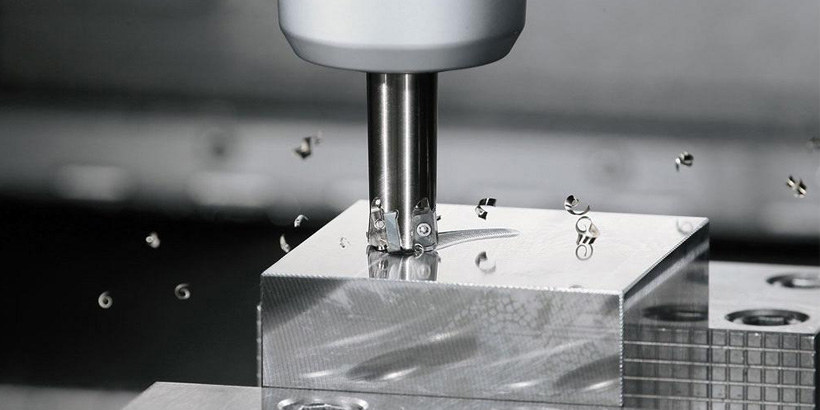

Grinding

This rough reducing process is normal in machining projects. The grinding wheel, which has abrasive grains, is made use of to remove the excess material on a surface. A grinding machine performs this procedure in the factory.

Typically made use of as an ending up procedure, the grinding machine is suitable for refining intricate components. With the capability to make precise items, this reducing process is made use of materials such as wax, foam, plastic, and also metal. Manufacturers use this process to produce components for cars and trucks, hydraulic tools, motorcycles, and also house appliances.

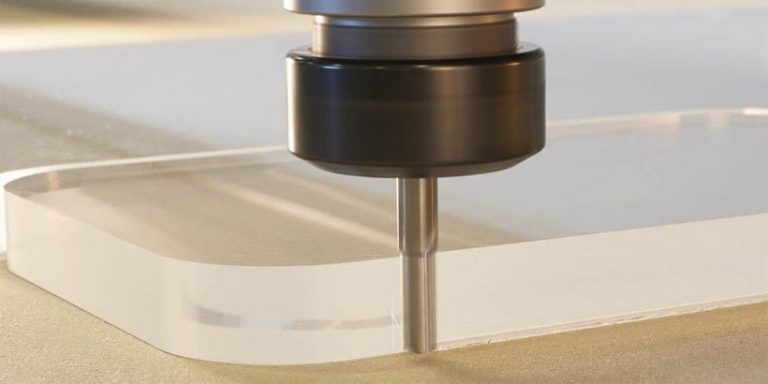

Milling

Performed by milling equipment, this procedure entails getting rid of material from a stationary work surface making use of a rotating cutting tool. These sorts of machining projects are useful when making a stepped or level surface.

Several of the materials made use of in this procedure consist of steel, carbon steel, aluminum copper, as well as stainless-steel. CNC milling services are used in machining projects in the auto market. They can develop parts of a motorbike, extra parts for an engine, as well as complete information about a vehicle.

Drilling/Boring

In a machining task, drilling creates round openings on a surface. Using a cutting device referred to as a drill, the holes are frequently produced to assist during the assembly process. On the other hand, boring is utilized to refine the accuracy as well as measurements of the made holes.

Exploration devices include two-edged revolving devices used to produce round openings that are alongside the axis. Boring is made use of products such as metal and wood utilized in the production of hefty tools.

You will discover these machines in the packaging and building and construction industries. Boring can be done by making use of a drill milling, press, or lathe machine.

Things To Take Into Consideration When Taking On Machining Projects

- Labor Prices: When managing your task, Worker prices are one of the difficulties you’re most likely to encounter. Some devices may need a machinist to manage them manually. Discover a balance between human labor as well as utilizing computerized devices.

- Selection of Material: When embarking on CNC machining tasks, the choice of product is essential. While the majority of equipment work with various types of products from steel, timber, porcelains, or plastic, it’s essential to make use of the correct choice. Product groups must take into consideration how the component will be made use of, the resistance, and also the project budget prior to choosing one.

- Expensive Devices: Most of the CNC machines are really costly. You will require to intend for regular assessment as well as upkeep to guarantee your machining task does not delay.

Just How To Beginning Affordable Machining Projects?

Machining tasks are a lot more cost-effective than other making jobs such as 3D printing. Let’s have a look at exactly how to run economical projects.

Usage Metal Materials

Machining projects are identified with metal cutting. If you are utilizing aluminum materials, machining is the most cost-effective approach, especially if you need to produce high quantities. CNC machining devices are well geared up to refine and cut steel as a resource.

Have the Right Equipment

Before developing any type of CNC parts, it’s best to make sure that you have the appropriate devices according to the raw products you need to utilize. Whether it’s plastic, timber, or metal, do your research study on the best devices to utilize.

Depending upon your job, there are a handbook and automated devices. Pick the necessary equipment to save on added expenses.

Invest In Software

Labor expenses that involve hiring human personnel are costly. To reduce such expenses, purchase modern software application and also train 1 or 2 machinists to take care of the projects. This method conserves your cash.

Economic of Scale

When beginning on a machining task, you can create much more systems. CNC machining is much more budget-friendly when developing prototypes in large amounts. There are expense advantages when utilizing this innovation.

Conclusion

Machining jobs have a considerable payment to the manufacturing industry. To continue to be affordable on the market, you need to invest in these innovations for premium products. CNC machining produces specific parts continually according to the client and also market specs and needs.

You need to extensively understand the different machining procedures entailed according to your anticipated output and also the difficulties to expect while functioning on the job. CNC machining projects can be extremely cost-effective if you focus on the vital requirements and incorporate affordable steps.