Milling Machine and Drill Press, What Is the Difference?

Drilling, as well as milling, are both machinings refines with great deals of similarities, it’s more important to find out their distinction when you intend to choose one of them for your job. Follow us to identify milling as well as exploration, also find out the difference between milling machine as well as a drill press.

Distinction Between Milling and also Drilling

CNC milling and drilling are 2 extensively made use of subtractive machining procedures that creating the desired part with removing materials. Exactly how to differentiate between drilling as well as milling, what are the precise difference between them?

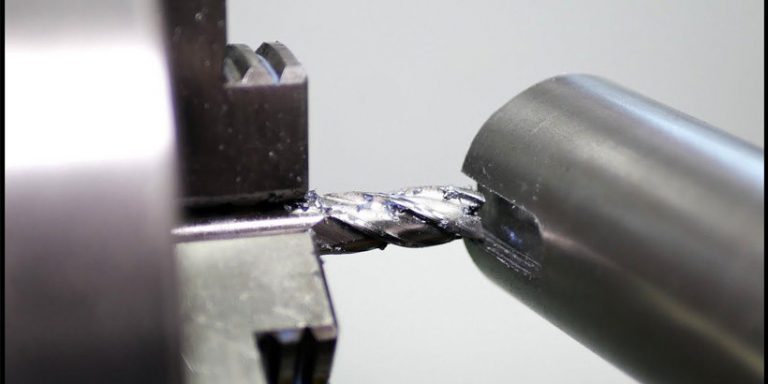

- Cutting tool. A milling cutter usually describes a multi-edge reducing tool with the shape of a solid of revolution, and the reducing teeth organized either on the periphery or on an end face or on both. Common milling cutters including ordinary crushing cutter, face milling cutter, side milling cutter, angle milling cutter, T-slot cutter, end mill, as well as a type milling cutter. The drill is around a rotary-end reducing tool, it can have either one or more reducing sides and also equivalent grooves, which can be straight or helical. Common drills including twist drill, core drills, gun drills, and spade drills.

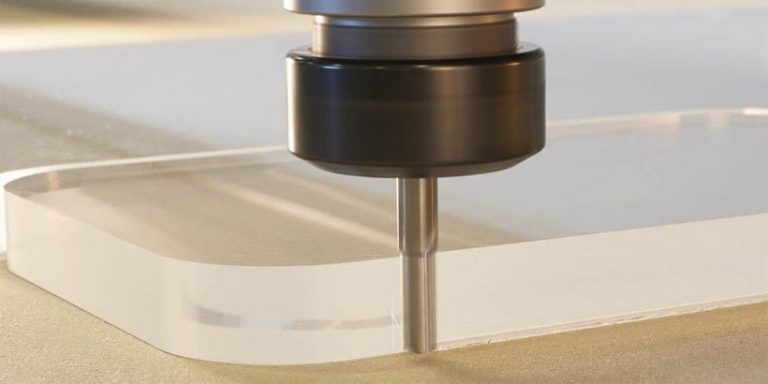

- Feed. For drilling, the feed direction is constantly axial to the cutter, the feed can be attained either by relocating tool or workpiece, while in milling, the feed can be given at any kind of angle to the axis of cutter, and the feed motion is usually finished by relocating the workpiece.

- Speed. The allowable cutting rates and also feeds for milling are three to four times greater than those for drilling.

- Contact with the work surface. In drilling, all cutting sides of the drill little bit continuously in contact with the part to be machined, in milling, the reducing side all at once disengages and involves the workpiece. Each reducing side cuts material from the work surface only for an amount of time throughout each tool rotation. This additionally leads to a difference in the size of chips.

- Working concept. Drilling entails producing openings by forcing a tool that rotates around its axis against the workpiece, the stock remains fixed on the table. In the milling process, material elimination is attained by incorporating the rotating motion of the milling cutter and also straight activities of the part simultaneously.

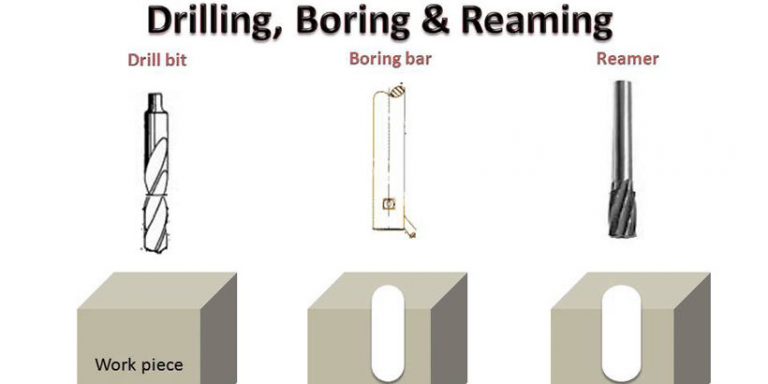

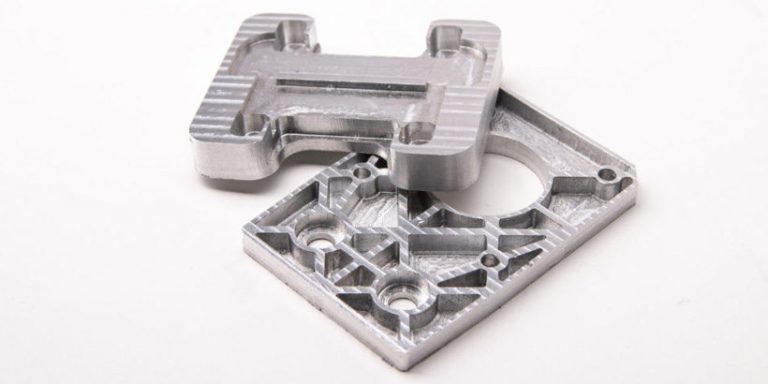

- Capabilities. Drilling or CNC drilling is a machining process made use of to create a through or blind opening in a workpiece. Milling operations can be used to develop level, contoured, and helical surfaces, for thread and gear cutting, and also more functions.

- Surface quality. Normally, the top quality of the surface areas machined by milling transcends to that of exploration.

- Machine. The exploration procedure can be performed by utilizing either hand drills or drilling machines, milling is only done with a milling device.

Distinction Between Milling Machine and Drill Press

- Axis of motion. The drill press just includes one axis of activity and can relocate either up or down along a straight line, it is suitable for vertical plunging yet can’t cut in the side direction, the milling machine allows the worktable to relocate the Y, z, and x instructions.

- Accuracy. The milling equipment can relocate all three axes all at once and the completed product has greater precision than that generated by the drill press.

- Size and weight. Drill presses are generally smaller in size and proportions than mills. Drill presses are usually lighter and often placed on top of the workbench and operated by hand, while milling machines usually directly set up on the floor and take much more space.

- Rotational speed. High RPM may trigger issues in chip discharge and breakage of drill bit, so the reduced rotational speed is often utilized on a drill press. Milling devices can use a high rotational speed.

- Capability and versatility. Milling machines are usually used to cut flat surfaces, they are also capable to create irregular surfaces and slots, as well as perform drilling, reaming, and other operations. The drill press is primarily applied to cut round holes in solid materials. A mill can work as a drill press and provide more capabilities.