Guide to Anodize Aluminum Components

Aluminium machined parts can be seen in the buildings, home furnishings, digital devices as well as even more fields, specifically the anodized aluminium, which is deeply liked by individuals as well as commonly made use of because of its one-of-a-kind buildings, smooth surface area finishes, visual appearance, infinite colours, as well as impressive durability. Right here DEK will present how to anodize aluminium in the house as well as the advantages of anodized aluminium.

Advantages of Anodized Aluminum Components

Level and smooth

A normal aluminium plate is easy to be uneven. The monotony of the anodized aluminium part has actually substantially enhanced in the surface area ending up process, and its production process can achieve better. The plated aluminium is much better than ordinary aluminium whether in the surface level of smoothness or monotony.

Elevated Appearance

The outside of the original aluminium plate is normally grey and looks unsightly, while where are abundant shades can be picked in the process of colour anodizing aluminium, attire and gorgeous, we have a lot more options to boost its look.

Corrosion and abrasion resistance

The anodizing process includes a coating as a safety layer on the metal surface, to stop it to get in touch with the media in atmospheres, which raises its anti-rust efficiency, corrosion, abrasion resistance and wear resistance, also extend the service life of the aluminium machined parts.

Excellent performance

Anodized aluminium plate not only has exceptional bendability but additionally entirely machinable. Various sizes can be made according to various needs, so regarding avoid waste. As well as its weather condition resistance is likewise very good, regardless of what type of climate condition, it can be made use of normally, even if in salt and also alkali acid rain.

Affordable

Price is typically among one of the most vital factors when we acquire things. The treatment process of the anodized aluminium plate is optimized, and also the manufacturing price of the product is decreased. The rate of plated aluminium components is budget-friendly.

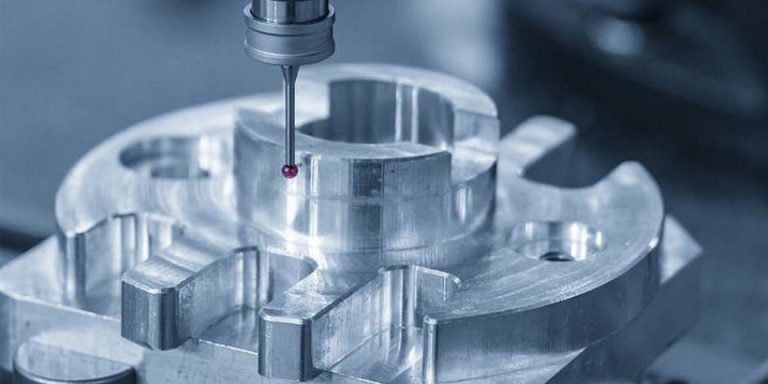

Exactly How to Anodize Aluminum Parts

Prepare what you need in aluminium anodizing

- Standard aluminium alloy components

- Container: thick plastic container or bin

- A fabric dye

- A degreaser product

- 2 lead long cathodes

- A roll of aluminium wire

- Enough distilled water

- Baking soda

- Rubber gloves as well as mask

- A number of gallons of sulfuric acid (battery acid)

- Lye

- A constant power supply of a minimum of 20 volts

Tidy the machined aluminium parts

Utilize the soap (or gentle cleaning agent) and also warm water to clean up off all the dirt on the aluminium part and completely dry it with a clean towel. Then use some degreaser to get rid of added oil from the component. Lastly, put the aluminium item into a scouring solution (44 ml of lye in 3.8 l of distilled water) to eliminate any existing anodizing externally, and also wash it completely with clean water after soaking 3 mins, note to wear rubber gloves.

Make the anodizing bath

The procedure must be carried out in a well-ventilated area, much better in 21 to 22 degrees Celsius. After picking the operating location, you can start to establish the power supply on non-flammable material. Attach the favourable cord from your battery charger or rectifier to a long aluminium cord and also attach your negative cable from your battery charger to an aluminium cable attached to 2 lead cathodes. Connect one end of the aluminium cord to the anode (aluminium component) and cover the middle of the cord around a slim timber plate, which is made use of as the leverage to raise the aluminium component out.

The next action is to blend distilled water as well as battery acid of 1:1 ratio in the plastic container, ensure the blend can immerse the aluminium anode. Attach the aluminium wire leads from the anode to the positive electrode of the power supply and also attach another aluminium cable from the lead cathode to the unfavourable electrode.

Anodizing and also dying aluminium

Turn off the power supply when the time is up and clean the aluminium component with distilled water. Place the aluminium part in the colour for about 15 mins. The last action is to take the coloured aluminium off on the tidy towel to cool it and also seal the surface. Turn on the power source to the ideal amperage (12 amps per every 0.09 square meters of material ) gradually. Keep the power supply constant for 45 minutes and prepare the dye in another container during the process.