Tips for Decrease Chatter in CNC Milling

Machining vibration is a usual issue in CNC manufacturing, which influences the quality and efficiency of the procedure, how to decrease chatter in CNC milling is the primary content we are mosting likely to speak about following.

What is Machining Vibration?

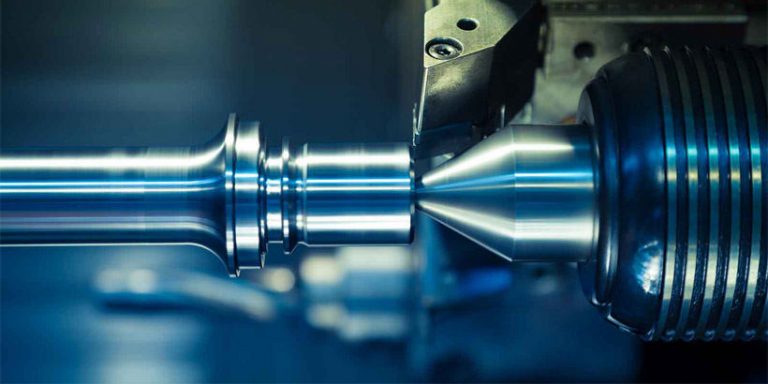

Machining vibration, additionally known as chatter, describes the vibration phenomenon in the cutting operation of machining process like CNC milling, turning and drilling, creates waves on the surface of the machined component. It happens when the workpiece and the cutting tool are vibrating at various frequencies. To put it in another means, the part and also cutting device moving various directions.

Why Need to Reduce CNC Mill Chatter?

Actually, correct vibration in CNC milling has a little result on machining quality. 100 μ m is typically considered as the criterion to evaluate whether the babble is appropriate. If the resonance amplitude of reduction exceeds 100 μ m, the device or work surface will be at risk of helping to loosen, as well as the milling can’t be proceeded. When the vibration is less than 100 μ m, although machining can be accomplished, there will certainly be noticeable resonance scratches on the surface of the component, which is not allowed on the completed surface. Machining vibration needs to be limited to a sensor array.

How to Decrease Chatter in CNC Milling?

Determine proper tool path

Milling can be separated right into down milling and also up milling according to the directions. The CNC milling machine, vertical machining centre that installed sphere or ball screw are extremely valuable to remove the CNC mill chatter in the cutting procedure.

Appropriate cutting

When the CNC milling machine uses a long and slim end milling cutter to mill the deep tooth cavity, it commonly embraces the dive milling, in which the cutter feeds axially like a drill a little bit. Change the cutting specifications might be reliable only when the reducing resonance is not severe. The cutting wedge angle of the blade is the smallest in milling.

Select the right tool

Furthermore, use sharp blades can minimize the cutting force of the CNC milling machine, the timely upkeep of the cutter and also the stability of the processing environment are the processing problems that can not be overlooked.