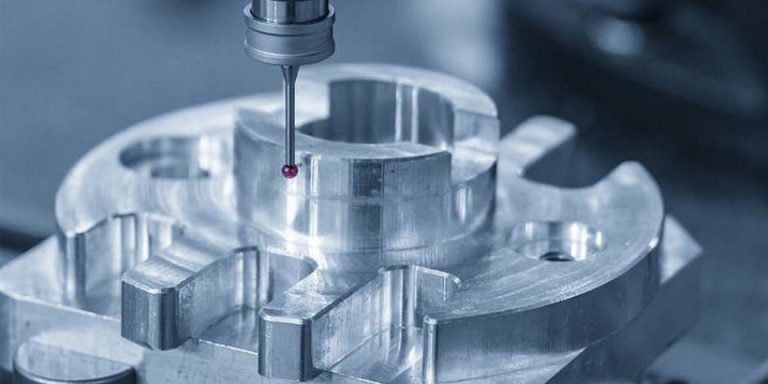

Guide to Find Issues in CNC Machining

Accuracy and precision are two crucial principles in measuring CNC machined parts, accuracy describes the nearness of the measured result to a detailed worth. But we often experience the mistake of CNC machines tools creates abnormal machining accuracy, the mistake is normally concealed and also difficult to diagnose. Follow us to discover the reasons that reduce CNC parts accuracy and also just how to figure out the issues.

Factors for Irregular CNC Machining Accuracy

The changes in the adjustment of the parameters of the CNC system, mechanical failure, and electrical parameters not maximized are common root causes of abnormal CNC machining accuracy in production. Find out the relevant failing factors as well as manage it, the equipment can return to regular and generate more accurate components.

The parameters of the CNC system modified or changed

In the process of repairing CNC machines, the void countered as well as backlash usually influenced by some operations. On the various other hands, major machinery wear or loose connection also might trigger the gauged worth of criteria transform, the criteria require to be changed accordingly to meet the requirements of machining accuracy.

Mechanical faults

Mechanical faults can create a cutting mistake, after that impact machining accuracy. When you leave out the possibility of hard mistake of electric control, inspect the machining program section that is running when the accuracy is irregular, especially the device length compensation, the calibration and also calculation of the machining coordinate system, and also court whether there is any kind of hidden danger in the mechanical facet through seeing, listening as well as touching.

The electrical specifications are not optimized, and also the machine operation is abnormal

Make use of the parameter feature of the CNC system, debug the electric motor, compensate for the backlash, adjust the servo gain specification and also get rid of the motor jitter.

Positional mistake

The positional mistake, programs, choice of cutting tools as well as various other elements will additionally result in irregular machining precision.

How to Locate the Reasons & Issues for Uncommon Machining Accuracy

From exterior to interior

CNC machine tools establish mechanical, hydraulic, electrical as one machine, so we can inspect out the issues from these three facets. The repair work personnel must inspect one by one from outdoors to within, trying to prevent the maker from being unsealed and also disassembled at will, or else the fault may be increased.

From mechanical to electric

Mechanical faults are less complicated to identify, while it’s harder to determine the troubles of the CNC system, removing the mechanical failing first can boost the efficiency of troubleshooting.

From off to on

Explore, test and evaluate without electrical power, to confirm there are no non-destructive faults, after that power on the maker tool, in the running problem, evaluate and check to discover the issue. For devastating mistakes, the danger has to be eliminated before changing on.

From easy to complex

When there are many kinds of faults in a messy, we ought, to begin with, the basic issues, after that consider difficult ones.