Guide to Abrasive Blasting

In this guide, DEK introduces the metal surface finishing technology- abrasive blasting or sandblasting with interpretation, types, application, and also benefits.

What is Abrasive Blasting or Sandblasting?

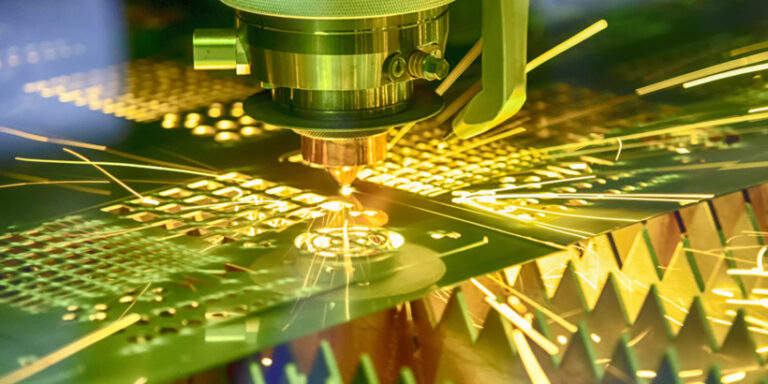

Abrasive Blasting additionally called sandblasting and grit blasting, refer to the procedure or operation of propelling a stream of unpleasant product made up of high-velocity sand-sizes fragments versus the metal surface under high pressure with blast tools like an air pressure system, to remove surface impurities, clean steels or enhance a texture, after that alter the level of smoothness or roughness of the surface. The rough product or blowing up media consisting of glass grains or smashed glass, aluminum oxide, silica sand, steel shot, baking soda, walnut shells, corn cob, and plastics.

Sorts Of Abrasive Blasting

- Vacuum Abrasive Blasting

- Centrifugal Abrasive Blasting

- Bead Blasting

- Wheel Blasting

- Automated Blasting

- Hydro blasting

- Air Abrasive Blasting

- Wet Abrasive Blasting

- Dry Ice Blasting

Applications & Uses of Abrasive Blasting

- Sandblasting can be utilized to remove rust, paint well as other contaminants from cars and buildings, machinery, and so on.

- Clean household devices, like screwdrivers, wrenches, as well as other rusty or unclean metal devices.

- Remove the little burs, tags, and extra product on the steel machining components.

- Develop signs, marks, statues and various other things on timber, steel or glass surface areas.

- Clean streets, walkways, and other concrete surface areas with the increased abrasives.

Benefits of Abrasive Blasting

- Versatility. An effective technique to cleanse a broad variety of surfaces rather than various other tools.

- Economics. The products used as abrasive media are often not pricey as well as recyclable.

- Preparation prior to coating. Prepare the steel surface area for reliable layer applications.

- Thoroughness. Easier and also more efficient to clean the crannies and nooks.

- Effectiveness. Clean the devices quick with outstanding removing abilities.

- Safety. The abrasive has inert nature and also will not respond with various other media.