Guide to CNC Vertical Machining Center

CNC machining center is a very automated multi-functional machine device that can be split into upright as well as horizontal machining centers, what’s the distinction between them? Below is the introduction to what is CNC vertical machining center (VMC) and the applications of VMC machines.

What is Vertical Machining Center?

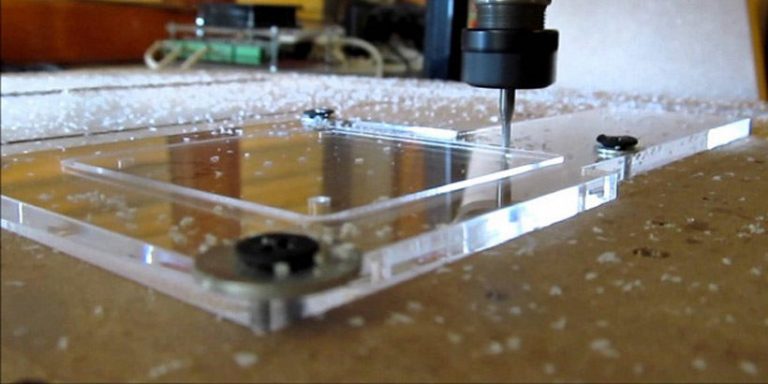

Vertical machining center (VMC) refers to the machining center of which the spindle axis as well as the worktable collection up and down, it can perform milling, boring, drilling, tapping, thread cutting, as well as more procedures. CNC vertical machining center is a type of Computer system Numerical Control VMC that has up and down oriented spindles that come close to work surface mounted on worktable from above and also outfitted with tool publication system as well as automatic device changer. In CNC vertical milling center, the product to be refined will certainly be held on the table and the round cutters oriented up and down on a spindle axis.

VMC Machine Applications & Utilizes

Due to its advantages and features, CNC vertical machining center can be applied in machinery manufacturing markets with high precision and also production requirements, such as aerospace, auto, textile, light and also instrumentation, electric as well as electronic, mould production, armed forces products, handicrafts, and so on. VMC is primarily suitable for refining work surfaces with complicated shape, high precision & precision and several procedures.

Box type components

Box kind CNC machined parts refer to the workpiece with over one hole system and many tooth cavities inside, primarily applied in device plane, auto and tool, like engine block, gearbox, spindle box, diesel engine block, gear pump shell, and so on. When using a vertical machining facility, 60%– 95% of the process of average machine tools can be finished in one-time securing. In addition, the CNC VMC has high accuracy as well as performance, rigidness as well as automatic device changing tool, as long as the process flow is well developed, correct fixtures and tools made use of, several problems of box kinds parts machining can be addressed.

Complex curved parts

In the aeronautics as well as transport market, the parts with the complex curved surface are widely utilized, such as cams, indispensable impellers of engines, propellers, mould tooth cavities, and so on. This sort of getting rid of a complex contour, surface contour, or box or covering parts with closed internal cavity is hard to achieve the fixed machining accuracy and find by traditional device tools or precision spreading. A multi-axis machining facility with automated programming innovation as well as unique devices can considerably enhance its production effectiveness and also ensure the form accuracy of the surface area, making the automated machining of complicated parts end up being very easy.

irregular or unique shaped components

Irregular machined parts have special shapes, the majority of them need multi-point combined processing of point, line and also face, such as bracket, base, etc. When machining unique-designed components, the much more complex the shape is, the higher the precision called for, while VMC reveals its advantages at such a minute.

Board, sleeve and also plate parts

This sort of workpiece commonly consists of a keyway as well as a radial hole. Completion confront with a hole system or bent plate as well as shaft, like shaft sleeve, plate with numerous holes, like electric motor covers, often uses a vertical machining facility; and straight machining centers are commonly utilized for getting rid of radial openings.

New parts in trial production

The machining center has high versatility and versatility. When the machining things are transformed, you only require to build and input new programs, also change some program sections or utilize some special directions sometimes. Utilize the zoom function can recognize machining of parts with the same form however different sizes, which offers wonderful ease for a solitary item, small-batch, multi-variety production, and brand-new product trial, and also greatly shortens the manufacturing preparation as well as test manufacturing cycle.

Distinction Between Vertical and Horizontal Machining Centers

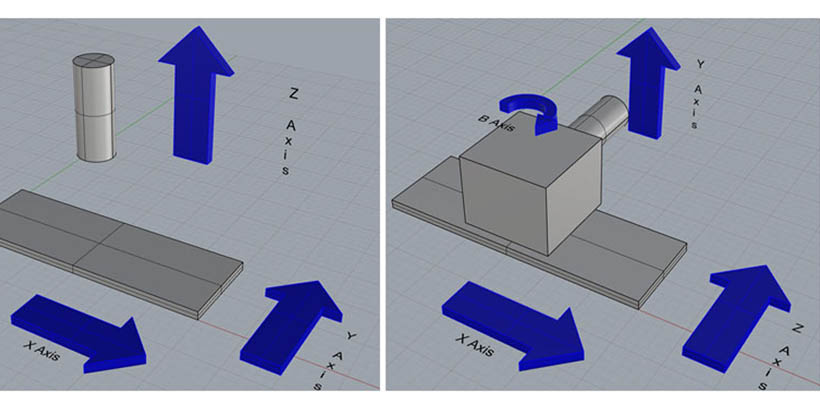

- A vertical machining center describes the machining facility with a vertical pin while the pin of the horizontal machining center is horizontal.

- The worktable of the vertical machining facility is rectangle-shaped and has no indexing turning feature. While the horizontal center normally has a rotating table with automated indexing.

- The horizontal machining center is easier to get rid of chips as well as decrease the damages to devices.

- The vertical machining center has an easier framework, a smaller sized flooring area, and also a lower rate.