Guide to Roughing in Machining

Machining is typically executed in 2 steps with different cutting criteria and offers differing results. Roughing is typically the very first procedure, which adhered to by finishing. Experience all the stages, the desired CNC products can be obtained from blanks. In this post, we put the concentrate on what is roughing in machining, the difference between roughing and finishing.

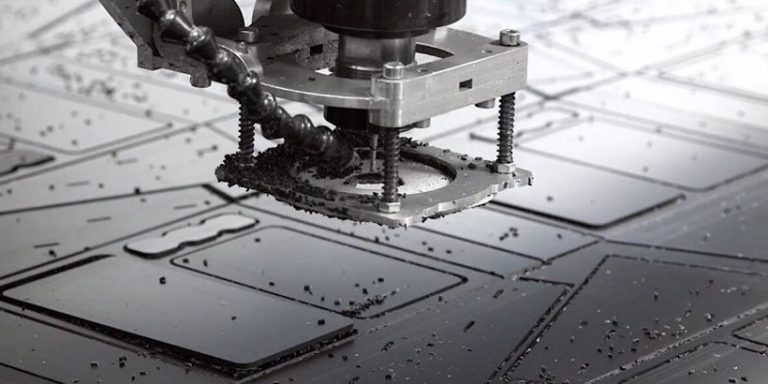

What is Roughing in Machining?

Roughing procedure in machining is generally utilized to eliminate mass material rapidly and also approximately form the workpiece to the desired type, in order to make the subsequent handling is extra effective and also hassle-free. The purpose of rough machining is to get rid of the empty allowance rapidly, huge feed rate and cutting depth are typically chosen to remove as several chips as feasible in a short time. Rough machined items usually obtain reduced precision, rough surface as well as high productivity. The roughing procedure is often the prep work of semi-finishing and finishing.

Benefits of Rough Machining

- Rough machining can discover various defects of the blanks, such as sand opening, air hole, inadequate machining allowance, and so on, which is convenient for timely repair or scrapping, so as not to waste processing time and price.

- After warm working, the residual stress and anxiety of the workpiece are big, different the rough and also surface machining, the ageing can be organized to eliminate the residual anxiety, as well as surface machining, can be arranged to remove the deformation after cooling down.

- The roughing operation can recognize rapid feed, and the error can be corrected by the following finishing, so as to make sure the quality.

- Split the processing phases, the advantages of rough and coating machining equipment can be fully utilized. Roughing equipment has high power, high performance as well as strong rigidness, and also ending up tools has high precision and reduced error.

- Roughing machining is set up prior to the mechanical rough and finishing can shield the surface area of various phases from wear.

Distinction Between Roughing and also Finishing

To meet the basic requirement of CNC machining, a number of operations need to be performed in the machine shop, including turning, milling, facing, and more. The roughing operation is utilized to generate a component geometry close to the shaped of the finished product in a short time, as well as the finishing procedure is executed after roughing to accomplish the last geometry as well as other information. What’s the specific difference between roughing as well as finishing?

- MMR. The material elimination price in the roughing procedure is higher than ending up.

- Surface finish. The surface top quality after completing is much better than that after roughing.

- Objective. Roughing is generally to remove a large quantity of excess material from the piece, ending up is to improve surface finish, tolerance, and decrease or lessen the mistakes.

- Parameter. Higher feed rate and also cut deepness are applied in roughing.

- Precision. Finishing or fine machining can supply high dimensional precision as well as close resistance while roughing can not.

- Cutting tools. Different degrees of roughness make different needs on the inserts and also reducing angles. negative rake inserts are the best fit for harsh machining given that they can take in cutting forces which enables higher cutting rates. With finish machining, positive rake inserts are typically selected to obtain a much better surface finishing.