An Overview to Benefits of Plastic Injection Molding for Medical Products

On a daily basis around the globe in health centers as well as clinics, research laboratories and colleges, many plastic products are used for clinical components, home appliances and also assistance tools. The range of applications is nearly unlimited.

And not just is injection molding versatile, yet likewise, several plastic materials have actually shown their utility and also quality in a variety of clinical items as well as tools that have currently received governing authorization. That implies it will certainly be relatively easier to get accreditation for brand-new clinical items using the same raw material.

To read more regarding why it could be right for you, here are the top 4 factors to consider plastic injection molding for making medical items.

Injection Molding is Perfect for Enclosures

Injection molding is especially useful when making enclosures as well as instances. It’s practically feasible to utilize a few other procedures to make a box, such as CNC machining or vacuum cleaner casting, and occasionally there are excellent factors for doing so. But those other manufacturing methods would certainly be much slower, consume even more raw material, and would certainly be excessively costly. When you do not want to invest in a device, that why this would certainly make sense just for low-volume or custom-made tasks.

Units come in all shapes and sizes. Some are simply simple parts like tool holding trays, pill dispensers or real estates for sensing units. Huge plastic real estates are especially helpful for innovative clinical devices. Not only is plastic light-weight, long-lasting as well as less expensive than an alternate product, it likewise will not interfere with electromagnetic power such as would certainly be used in PET CAT scans, MRIs and also x-rays. And some plastics materials are additionally untouched by radiation.

Process Control as well as Reliability

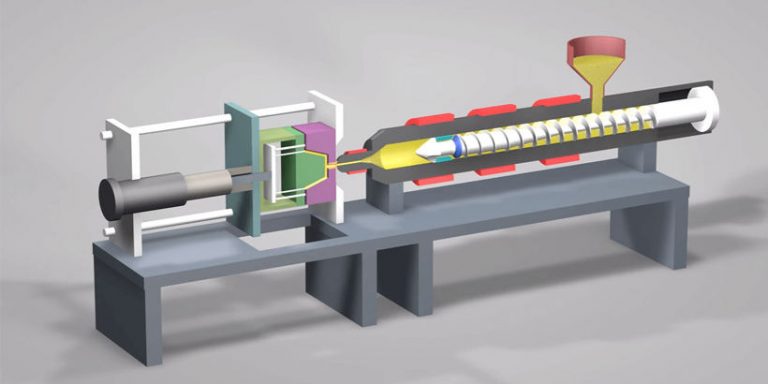

The background of plastic injection molding returns nearly 100 years. That suggests the procedure of injection molding has actually been constantly improved and improved to the point where it’s really stable and also trustworthy. There is progressed modeling software application available that takes much of the uncertainty out of the tool style. And also, with contemporary electronic controls on plastic injection molding machines, the procedure specifications can be promptly tuned for optimum performance as well as to lower manufacturing lead time of injection formed medical items to a minimum.

Injection Molding can Produce Medical Products in High Volumes

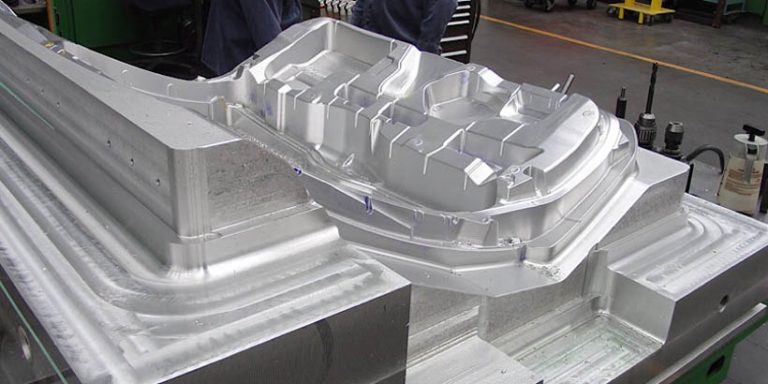

All injection molding jobs, including clinical ones, initially start with a molding device and pass away. To make an intricate shape may call for making an equally complex mold and mildew tool, so there is an initial item advancement financial investment that requires to be considered prior to a single clinical component is made.

But once the device is approved it’s possible to make numerous hundreds of duplicate clinical components in plastic really swiftly as well as financially. Bigger production volumes have a tendency to recoup the tooling costs over time due to the fact that of lower price-per-part. That’s why injection molding is excellent for rather generic things like containers, tubes or disposable single-use medical items like syringes.

Injection Molding Supplies Adaptability for Medical Products

As well as the good news is numerous of these resins are suitable for medical applications. Plastic is significantly popular when used for prosthetics, replacement joints or various other medical items that will be in long-term contact with the body.