CNC Router VS CNC Mill, What is the difference?

A gantry-style milling machine is often described as the router, what is the distinction between a CNC router and also CNC mill? And what are they used to do? From materials, rate, axes, cutting location or depth and also even more aspects, follow us DEK to understand even more regarding the mills as well as routers.

What is a CNC Mill?

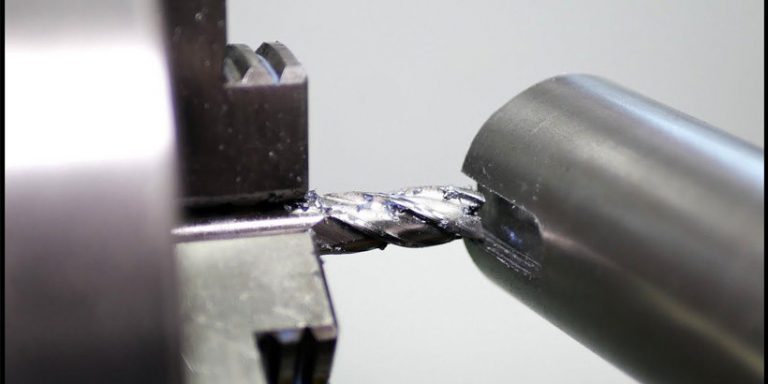

CNC mills or milling machines are used to do the milling process, uses a revolving cylindrical reducing tool that can relocate along multiple axes to reduce the work surface and generate various functions like ports, openings, forms and more, while the work surface relocates throughout the milling cutter in a details instructions. CNC mills can make practically all of the materials, consisting of metal, wood, ceramic, plastic, and so on, yet steel CNC milling components are much more common.

What is a CNC Router?

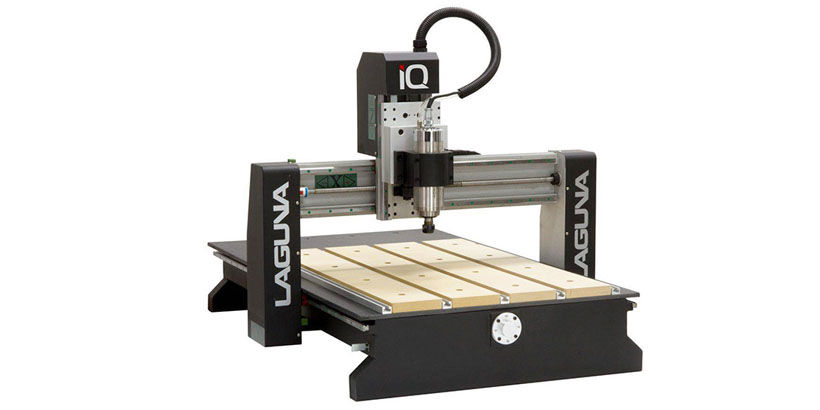

CNC router is a cutting machine managed by computer numerical devices, utilized to generally cut products like wood, compounds, aluminium, foams, and also plastics, frequently produces door makings, interior and exterior decors, wood panels, signboards, wooden frameworks, mouldings, musical tools, furnishings, it’s also readily available in cutting mortises, tenons, panel saw, as well as the spindle moulder.

The Distinction Between CNC Router and CNC Mill

- Movement. CNC mills typically move in an X-Y configuration and also the spindle moving on a linear axis over the work surface, while CNC routers are installed on a stationary table, with a spindle moves along 3 axes: X, Y, as well as Z.

- Torque. CNC mills utilize torque to make cuts, and also CNC router has much less torque, it makes use of rotational rate to drive the force.

- Mass or quality. The mass of a CNC milling machine is typically larger than that of a CNC router.

- Application or components. For example, the component or component for crucial tools for aerospace needs high precision as well as details offered by CNC mills, but for less demanding applications. CNC routers may suffice.

- Cutting area. CNC router has a bigger cutting area as the materials like wood often comes in large sheets, while the milling device provides a much deeper cut.

- Cost. The cost of a CNC mill will certainly be higher than that of a router equivalent in dimension.

- Materials. CNC routers are most often used to reduce softer materials like plastic, foam and also wood, while mills usually manage steels and tougher products.

- Speed. CNC routers are typically run at broadband, as well as the CNC mills are slower.

- Accuracy. A CNC router is not as precise as a CNC mill, which is a far better selection for high accuracy machined components.

- Axis design. The larger clearance along the Z-axis make the CNC milling machine suitable for thicker cuts as well as even more complex layouts.