Difference Between ABS And PLA

PLA and ABS prevail materials in manufacturing, we obtain asked that PLA vs ABS, what’s the distinction? From the interpretation to properties to application, we’ll describe the PLA as well as ABS in detail, also compare ABS as well as PLA filaments in printing.

What is ABS?

ABS (Acrylonitrile butadiene styrene) is a common thermoplastic polymer and also a terpolymer made by polymerizing styrene as well as acrylonitrile in the visibility of polybutadiene. Three monomers, blended together as well as linked together, creating the copolymer ABS. The butadiene in this mix gives ABS its regular milky, beige color, and depending upon exactly how the ABS plastic is made, it stays as bigger or smaller sized particles within the mix, it also provides ABS its strength, which it is understood for. ABS plastic is inflexible, challenging, impact-resistant with a moderate usage temperature level, which helps it a daily usage plastic. It is easy to mold, with low shrinking, less warpage, and supplies an excellent surface finishing.

Feature of ABS

- Density: 1.02-1.21 g/cm3.

- Glass transition temperature: 90-102 ℃.

- Young Modulus: 1.79-3.2 Grade point average.

- Toughness: 200-215 J/m.

- Strength at Yield (Tensile): 29.6-48 MPa.

- Strength at Break (Tensile): 29.8-43 MPa.

- Stiffness (Flexural Modulus):1.6 -2.4 Grade point average.

- Hardness Shore D: 100.

- Elongation at Return: 1.7-6%.

- Elongation at Break: 10-50%.

The applications of ABS

The features, as well as buildings, make the ABS injection molding parts as well as squeezed out items are widely made use of in pipe systems. Various other applications of ABS plastic consisting of music instruments, key-board keycaps, golf club heads, automotive edge parts, medical & medical non-absorbable sutures, ligament prostheses, drug-delivery systems tracheal tubes, units for electric and also electronic settings up, toys, family and also durable goods, colourant, and so on. ABS is likewise used as a filament for 3D printing by FDM (integrated deposition modelling), and perfect for the manufacturing of prototypes.

What is PLA?

PLA, the acronym of Polylactic Acid, is a thermoplastic polyester and naturally degradable plastic, made from renewable energies like starch. It is created with condensation polymerisation (loss of a water molecule). PLA was first developed in 1954 as well as readily produced in the 1990s, then growing in numbers.

Feature of PLA

- Polymer density: 1.21-1.25 g/cm3.

- Tensile toughness: 21-60 MPa.

- Tensile modulus: 0.35-3.5 Grade point average.

- Ultimate strain: 2.5-6%.

- Details tensile strength: 16.8-48.0 Nm/g.

- Particular tensile modulus: 0.28-2.80 kNm/g.

- Glass transition temperature level: 45-60 ℃.

- Melting temperature: 150-162 ℃.

The application of PLA

PLA is the most thoroughly researched and also utilized renewable aliphatic polyester, it has a tested possibility either to replace standard petrochemical-based polymers for industrial applications or as a leading biomaterial for countless clinical applications. PLA is a really great selection for 3D printing, PLA is very easy to publish with relatively reduced temperatures, it will stick well enough to many bed surface areas other than perhaps raw aluminium or bare PCBs, as well as it’s actually mechanically fairly strong. The usual uses of PLA likewise consisting of plastic bags, plastic containers, trash can, food covers, textiles fibres, vehicle components as well as more.

Difference Between PLA and also ABS

PLA, as well as ABS, are similar in some facets, such as the cost, you can locate more spending plan selections based upon your objectives. However, they vary a whole lot when it comes to toughness, warmth resistance, various other properties as well as applications.

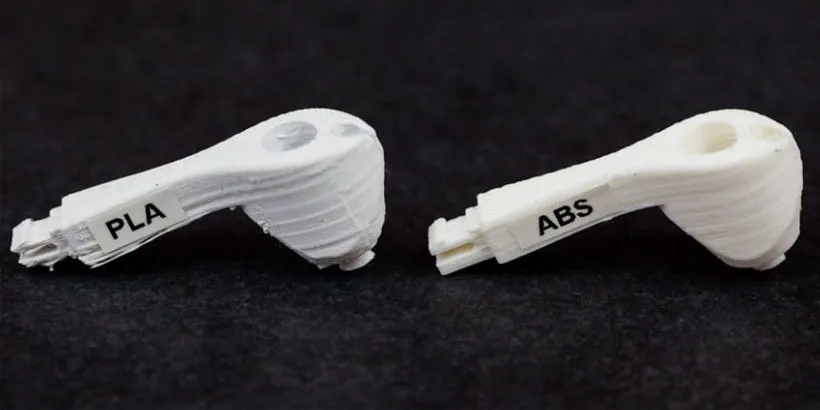

Surface finish

FDM 3D printing makes both ABS and PLA prints obtain visible layers. ABS normally is available in a matte coating, as well as PLA has a glossier surface.

Properties

- Compared to PLA, ABS makes the most of ductility, flexural strength as well as prolongation prior to the damage, which makes it a favoured option for numerous prototyping applications. If the form matters greater than a feature, PLA printed component seems a lot more popular.

- The glass transition temperature level of ABS is greater than that of PLA, so ABS has higher heat resistance than PLA, which easily sheds its structural stability in a high-temperature setting. ABS often tends to split in a cool atmosphere, while PLA doesn’t. PLA does best in projects with reduced mechanical or thermal needs due to its reduced solvent as well as water resistance.

Biodegradability

PLA is a bioabsorbable polymer as well as among one of the most appealing biopolymers because of the truth that the monomers might be produced from safe renewable feedstock as well as a result of being a normally happening natural acid. ABS is not eco-friendly, yet it is recyclable.

Applications

- PLA is less complicated to publish with than ABS, as well as it appropriates for 3D printing components where looks values as well as great details required. PLA is also commonly used by newbies and also hobbyists that simply getting started on the planet of 3D printing.

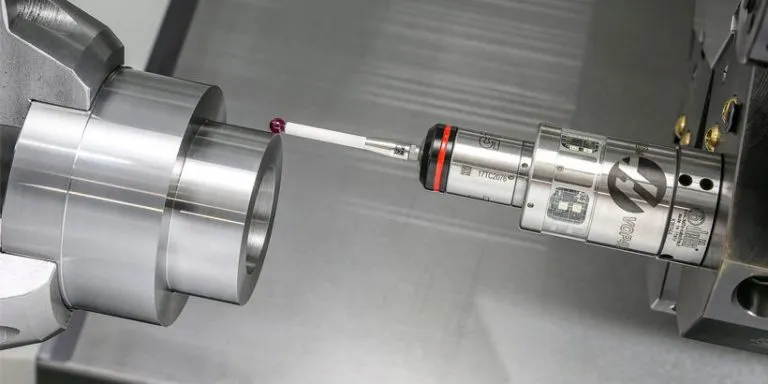

- ABS is a much better option when toughness, ductility, thermal security and machinability are very important. Its longevity makes it typical for end-use products such as protective instances.

- General, PLA is more prominent in 3D printing, even though it’s not ideal for heavy-duty practical components, while ABS is an extra commercial and also engineering material that can be made use of in CNC machining as well as shot molding.

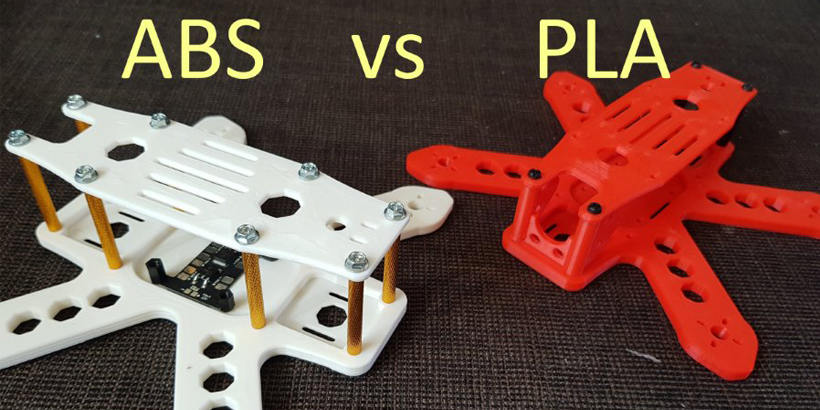

ABS vs PLA filament, what’s the difference?

- ABS printing requires greater nozzle and bed temperatures than PLA, particularly the print bed. Typically, ABS filaments require a bed temperature level between 80 ℃ to 110 ℃, PLA filaments usually use 60 ℃ bed and also even no heated bed.

- When it concerns odours, the toxicity of ABS is obviously greater than that of PLA, and it can produce an awful odour. When the covering is lifted, smoke might be launched instantly, making the odour often excruciating.

- ABS is a bit stronger than PLA, which resulting in its printing trouble somewhat.

- ABS prints often tend to be much less brittle than PLA parts, which suggests that the adaptability of ABS is much better.