Guide to 110 Copper

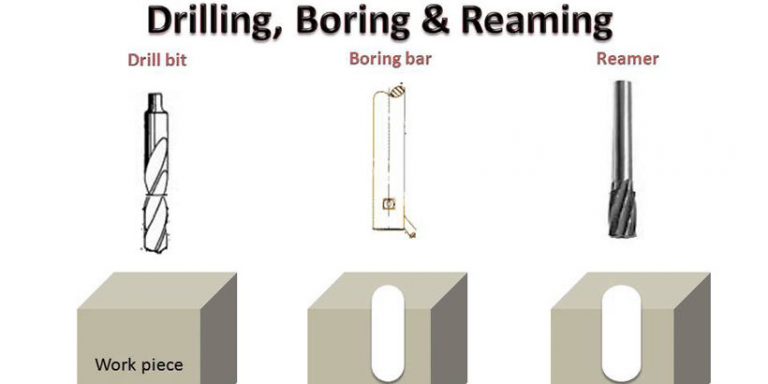

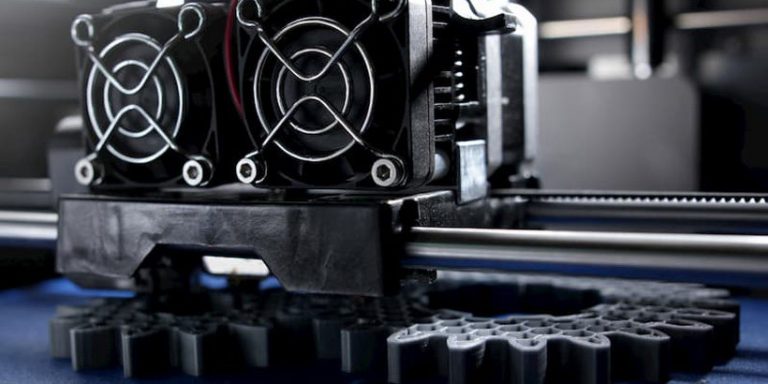

Do you need mechanical parts made of copper 110? Does it machinable? In this short article, DEK will certainly introduce what is 110 copper with its properties and the difference between copper 101 and also 110 We can offer cost-effective CNC machining options to meet your needs of copper parts. Find out about the features of Copper CDA 110 in the message and also the information sheet.

What is 110 Copper?

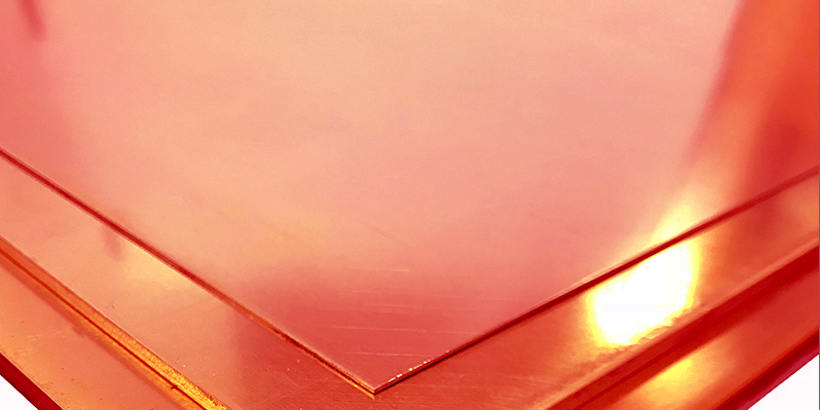

110 copper, an electrolytic difficult pitch (ETP) Copper, also referred to as UNS C11000 and CDA 110, has 99.99% copper. Copper alloy 110 can be offered in great deals of shapes, like rounds, squares, sheets, plates, and also flats. Because of the superior mechanical homes, Cu-ETP is functional to be made as CNC machining copper components utilized in a variety of applications, especially the electrical tools as well as items like cables, overhead line conductors, generator windings, and also coaxial lines, thanks to its high electrical conductivity.

Functions of CDA 110

- Exceptional electric as well as thermal conductivity.

- High corrosion resistance

- High ductility

- Anneal immune

- Readily chilly worked when heated up

- Not vulnerable to embrittlement

- Great cold and hot developing qualities

- Excellent forgeability

Applications of 110 Copper

What is 110 copper made use of for? Copper 110 is perfect for digital applications calling for free from damage as well as air pollution by dangerous pollutants as well as oxides. 110 copper can also be gotten a diversity of markets as well as products, such as warm exchanger elements, automotive ignition system electrodes, pipes installations, electrical components, waveguides, base plates, bus bars, blade as well as ring terminals, cords, power transmission components, resistance welding electrodes, terminals, elements for vacuum gadgets, switches, interrupters, deposition systems, electron tubes, glass-to-metal seals, superconductive magnets components and even more.