Guide to CNC Machine Device Probing for Component Measurement

The dimension of the work surface in the manufacturing process is crucial for attaining precision. CNC machine device probing system is the evaluation and measurement device for accurately machined components placed on the worktable. What can the machine tool probing do? Follow us to discover the probe system operates, advantages, as well as applications.

What is Machine Device Probing System?

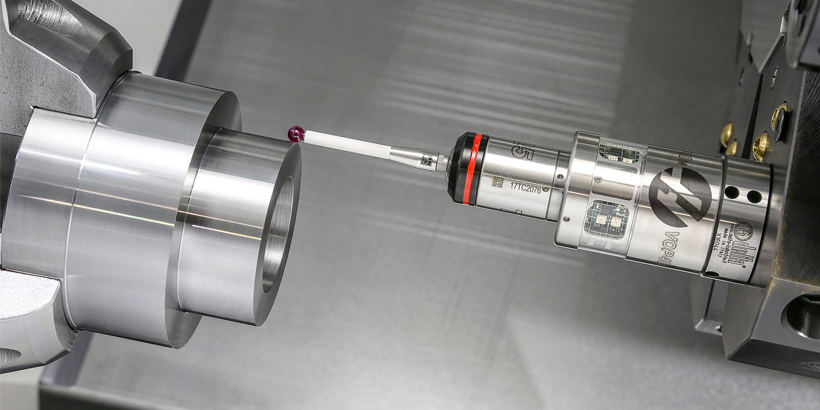

A probing system is a gauging tool configured on CNC devices to gauge the functions of CNC machined parts, fix the coordinate system, identify the mistake, etc. after the last or partial machining procedure, which can improve the machining quality of the production equipment, reduce expense as well as conserve time.

What is CNC Machine Device Probing Used for?

The features of the machine tool probing on CNC machine:

- Instantly determine the accuracy mistake of machine device and makeup

- Immediately focusing, mapping edge, determining as well as correcting the coordinate system, make tool compensation

- Measure the surface directly on the device for a big, intricate workpiece

- Contrast the measurement results as well as create a report

- Improve producing efficiency, top quality and also make certain the item credentials price

- Boost the capacity and also the accuracy of device devices, appropriate huge single-piece part in one-time, prevent 2nd clamping

- Minimize time for equipment tool help

- Decrease producing cost of part datums

- Tool setup and also fixture arrangement

- Digitizing/scanning

- Various other functions

Advantages of CNC Machine Device Probing System

- After the CNC machine tool is equipped with the machine device probe, the online measurement can not just gauge the geometrical tolerance of the component, help with the installation and also adjustment of the workpiece, simplify the component, reduce the complementary time and also boost the manufacturing efficiency, yet likewise immediately modify the programming and also improve the processing precision according to the measurement results.

- Machine device probe can significantly improve the general efficiency of CNC machine tools and conserve expenses, also make sure manufacturing high quality as well as enhance productivity for a very long time.

- Throughout the machining process with CNC devices, the equipment tool probe can give an alarm in time for the workpiece out of tolerance, device wear as well as damages, and make compensation or exchange the tool, which rather than the hand-operated assessment, conserves time cost, and greatly improves the automation of the machine devices.

Applications of Machine Tool Probing

The early application of machine device probe is to provide a repair service scheme for the machining of intricate rounded surfaces such as big gears. With the advancement of the integration of on-line dimension as well as machining of CNC machine tools and also the development of equipment tool probe innovation, the machine device probe on the market now can attain a lot more purposes, and the dimension placing accuracy as well as automation degree is additionally boosted.

The machine device probing systems can be utilized on CNC machining facilities, lathes and more tools to establish as well as determine up parts, monitor workpiece surface area condition, measure attributes, as well as validate completed part measurements.

The probe of the machine device is the most effective choice of machining complex curved surface area. It can recognize automatic dimension as well as processing at the same time on the machine table, which not just guarantees the precision of the CNC machined parts, however also makes sure the machining effectiveness, fulfils the production need of precision, high-speed as well as high-efficiency of set machining manufacturing.