Guide to CNC Machining

CNC machining is a manufacturing process in which pre-programmed computer system software determines the motion of manufacturing facility tools and machinery. The procedure can be used to control a variety of complicated equipment, from grinders as well as turrets to mills and also routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a solitary collection of motivates.

Short for “computer numerical control,” the CNC procedure runs in contrast to– and thus supersedes– the restrictions of manual control, where real-time operators are required to trigger and also assist the commands of machining devices through wheels, bars and buttons. To the observer, a CNC system may look like a regular set of computer system components, yet the software programs and also gaming consoles used in CNC machining differentiate it from all other kinds of computation.

Things to Learn About CNC Machining

When a CNC system is turned on, the desired cuts are configured into the software as well as determined to matching devices and equipment, which perform the dimensional tasks as defined, much like a robotic.

In CNC shows, the code generator within the mathematical system will certainly typically assume mechanisms are remarkable, in spite of the possibility of mistakes, which is higher whenever a CNC machine is routed to cut in more than one instructions all at once. The placement of a device in a mathematical control system is laid out by a series of inputs known as the part program.

With a numerical control machine, programs are inputted via strike cards. By comparison, the programs for CNC machines are fed to computer systems through small keyboards. CNC shows are kept in a computer’s memory. The code itself is written and edited by developers. CNC systems supply much more extensive computational capability. Most importantly, CNC systems are never fixed, because newer motivates can be contributed to pre-existing programs through revised code.

CNC Machining is Fully Automated

In today’s CNC protocols, the manufacturing of parts by means of pre-programmed software application is mainly automated. The dimensions for an offered component are set right into location with computer-aided design (CAD) software and after that converted into an actual final product with computer-aided manufacturing (CAMERA) software application.

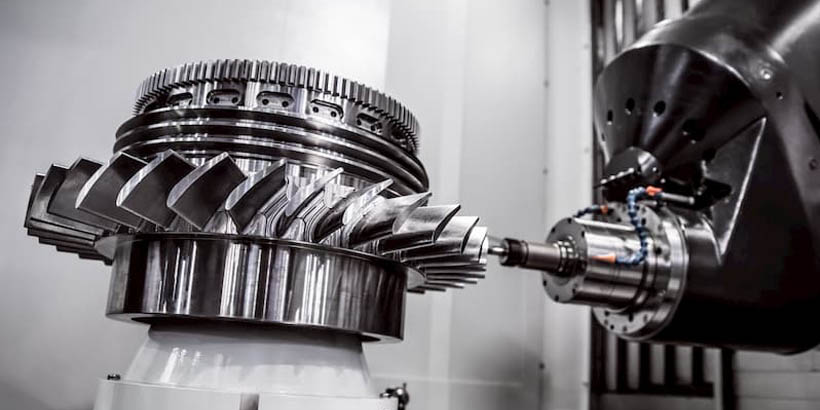

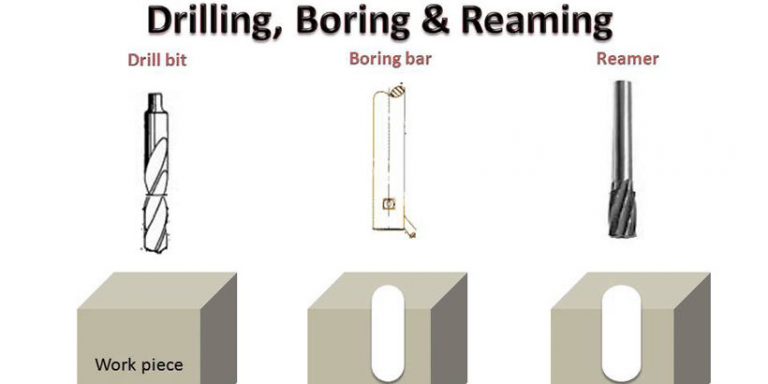

Any given workpiece can demand a range of machine tools, such as drills and cutters. In order to suit these needs, many of today’s machines combine numerous different features right into one cell. At the same time, an instalment might contain a number of makers and a collection of robotic hands that move parts from one application to an additional, but with whatever regulated by the exact same program. No matter the configuration, the CNC process allows for consistency partially manufacturing that would certainly be tough, otherwise difficult, to duplicate manually.

CNC machining is one of the most vital features of the manufacturing sector, from the production of computer components and fasteners to automobile parts and aerospace elements. Without the sophisticated capabilities, one-of-a-kind to CNC machines, different components seen on everyday home products would be virtually difficult to generate. As the designers who have actually gone through CNC machine training will attest, the coding that makes it feasible for a CNC machine to mould metal parts into form is complicated.