Guide to Knurling & Knurling Tool

Screwdrivers, device handles and also grips of a variety of products are commonly knurled. Based on the knurling on CNC lathe machines, we’ll go over the usages, devices, problems as well as suggestions during the knurling procedure.

Table of Contents

What is Knurling?

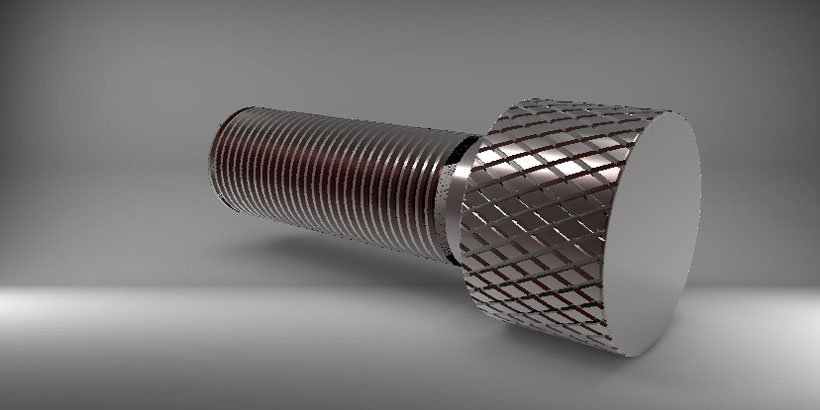

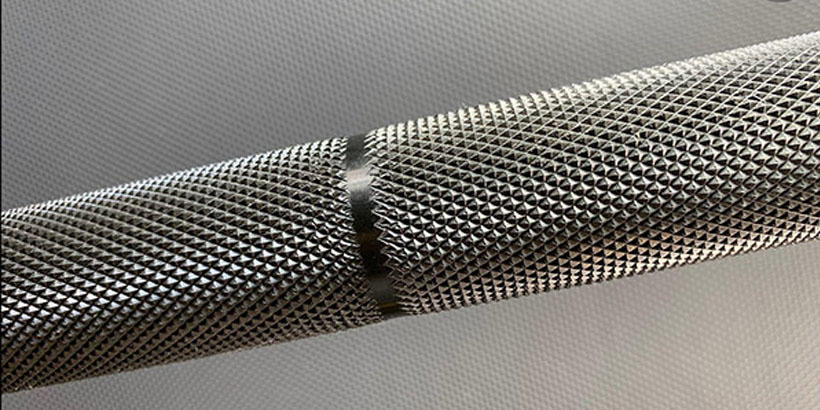

Knurling is a manufacturing process as well as the method of developing concave and bumps on the surface of the workpiece, presented as the pattern of straight, tilted or went across lines is rolled into the material, the knurling procedure is normally performed on the lathe machine, consisting of CNC turning lathes. The gone across knurled patterns including ruby and square, with different angles.

What is the Purpose of Knurling?

- Knurling offers a far better grasp for fingers to comprehend the knurled components and also products via increasing the friction.

- Knurling can be used to make or fix up the endure machined part with the increased area.

- Knurling is likewise an approach when putting together low precision elements.

Tools of Knurling on Lathe Machine

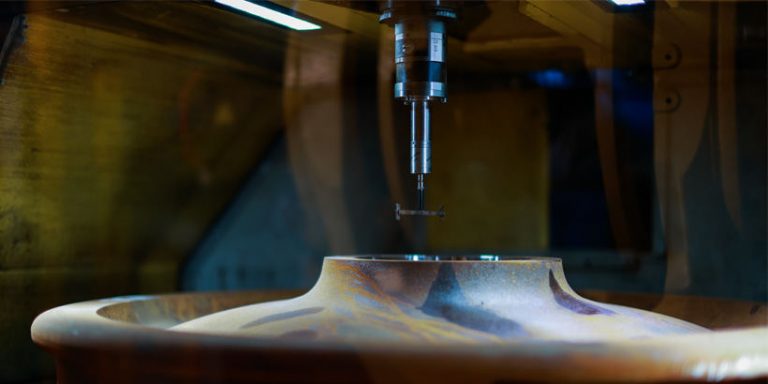

The knurling operation needs a knurling tool, which is a handle with a knurling wheel. A knurling device is utilized to push the wanted knurled pattern on the surface or area, just how does it work on a lathe machine? When the turning turret is set, the chuck placed and begin revolving at a reduced rate, the knurling device press against an item of a rounded section of the workpiece, after that enhances the pressure gradually until the pattern is created.

Typical Troubles and also Tips for Knurling on (CNC) Lathe

During the knurling procedure, there may be disordered, vague and also even wrong patterns made due to some factors such as the rotary rate of the device is too high; insufficient rigidness of fixtures or tool turret; do not start cutting after the pattern to roll clearly; steel chips protect against the knurling procedure. Efficient steps ought to be required to solve the troubles.

Tips for Knurling on Lathe

- Turn on the device after the pattern is generated plainly.

- Use appropriate lubing fluid, the mechanical oil can be used.

- Clean the chips often.

- The rotating speed ought to not be too high.

- Change much better quality coolant, increase water pressure to cleanse the area to be processed.

- Usage double wheel knurling tool, since the call area with the item, is smaller, and the device pointer is simple to be washed. Additionally, the double wheel knurling tool generates an even more clear pattern and minimizes radial force.

- The force is large when knurling on the lathe, the workpiece has to be secured strongly.

- When assembling the knurling tool, the cutter face ought to be vertical to the component.

- The start of knurling is very important, press the device onto the item without time out, so regarding roll the pattern at the same time.