Guide to pick the right cutter and programs for CNC

The option of CNC cutter, as well as the decision of cutting amount, are very important components in the CNC machining process. It does not just affect the machining effectiveness of CNC machine tools, but additionally straight influences the processing quality. The advancement of CAD or CAM innovation makes the layout of CAD straight utilized in CNC machining, specifically the mix of DNC system microcomputer and also the CNC machine, making the entire procedure of layout, procedure planning and programs finished on the computer, as well as not requiring to output unique process files usually.

Today, numerous CAD or CAM software program offers automatic programs functions. This software usually prompts the process planning relevant concerns such as cutter options, machining path preparation and reducing use setups in the program’s interface. Developers just require to establish the relevant criteria, the NC program can be instantly produced and transferred to the CNC machine for machining The cutter choice and reducing quantity determination in CNC machining is finished under the human-computer communication state, which is in sharp comparison with the ordinary maker device processing.

At the same time, the designer must also understand the fundamental concepts of cutter selections and also reducing amount decision. The developer needs to totally take into consideration the attributes of CNC machining and can appropriately select the cutting device and the cutting quantity when programs.

Kinds and characteristics of commonly utilized cutting tools for CNC machining

CNC machining cutting tools have to adapt to the high speed, high performance and automation of CNC machine devices. CNC cutting tools can be categorized by lots of methods.

CNC cutting tools can be split right into high-speed steel cutting devices, hard alloy cutting tools, diamond cutting tools, cubic boron nitride cutting devices as well as ceramic cutting tools based upon the devices’ materials.

Over the last few years, securing turning cutting devices have been widely used in order to meet the demands of CNC machine tools such as being durable, steady, easy to adjust and exchangeable, getting to 30% to 40% of the whole CNC tools in quantity and 80% to 90% of the total metal elimination.

Compared with the cutting tools used for ordinary device, CNC cutting devices ought to have functions of having great rigidness (specifically harsh machining cutting devices), high accuracy, anti-vibration and also tiny thermal contortion, good interchangeability, fast substitute of the cutting tool, lengthy service life and being stable and dependable cutting performance, conveniently adjust and transform device to conserve time and also standardized for shows and device management.

CNC machining cutter choices

The cutter, as well as the cutter holder, must be picked correctly according to the machining ability of the machine device, the efficiency of the workpiece product, the machining process, the cutting quantity and also various other appropriate aspects. Under the property of fulfilling the processing needs, try to choose a shorter tool owner to enhance the rigidity of the tool handling.

About DEK

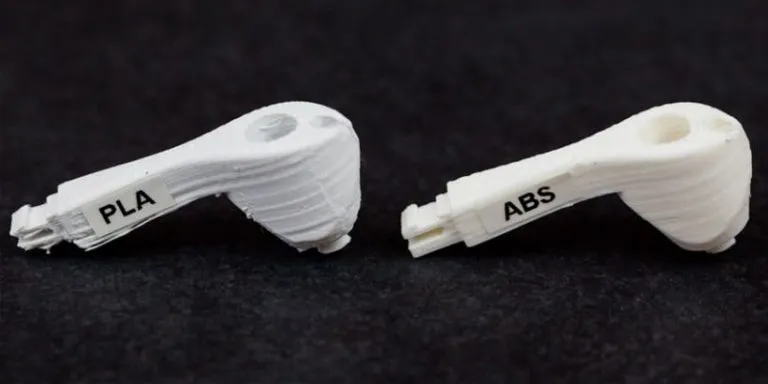

DEK, found in 2002, was a machining factory at the beginning. For decades, through continuous investment in equipment, and continuous investment in other companies, now DEK is a China leading full services company of CNC machining, precision machining, 3D printing, plastic injection moulding, which helps customers achieve their products from design to mass production.

If you need a prototype, medical equipment parts, precision aluminium parts, or any other plastic and metal parts, there is no better supplier than DEK. We have a variety of processing equipment and sophisticated testing equipment, enough to deal with any complex or tight tolerance products.