Guide to Rapid Prototyping

From a suggestion to the final finished item might experience a lengthy process, in order to obtain the excellent item especially in big sets manufacturing, rapid prototyping is a cost-efficient and also rapid method to aid developers to construct, verify and realize their ideal ideas rapidly since solitary part or 3D model of product can be tested as well as boosted throughout the process. Discover what is rapid prototyping as well as its benefits, advantages, downsides, kinds of techniques, services, and also methods.

Table of Contents

What is Rapid Prototyping?

Coming to the rapid prototyping interpretation, the term is originated from the manufacturing market. Fast prototyping or fast prototype is the procedure of entails a collection of lots of techniques used to swiftly make a physical component, model or setting up utilizing three-dimensional CAD (computer-aided design) data. The model can be tested prior to mass production of the part. The building of the component normally uses 3D printing or additive manufacturing innovation. In the process of development, the engineering product layout can be examined aesthetically and also functionally. rapid prototyping can likewise visualize what an application or an internet site will certainly appear like to obtain feedback and validation from developers, customers, and also designers.

How Does Rapid Prototyping Work?

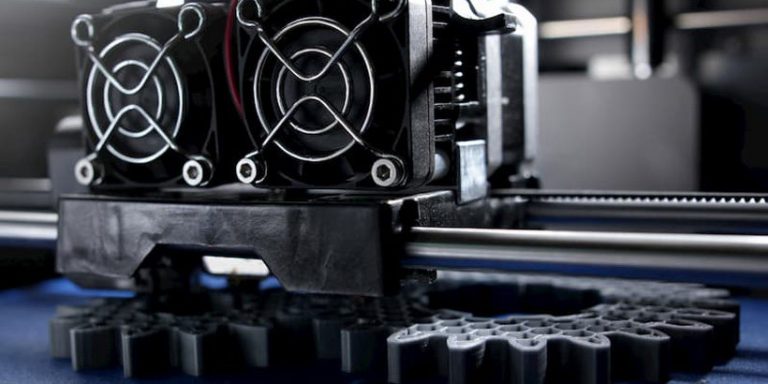

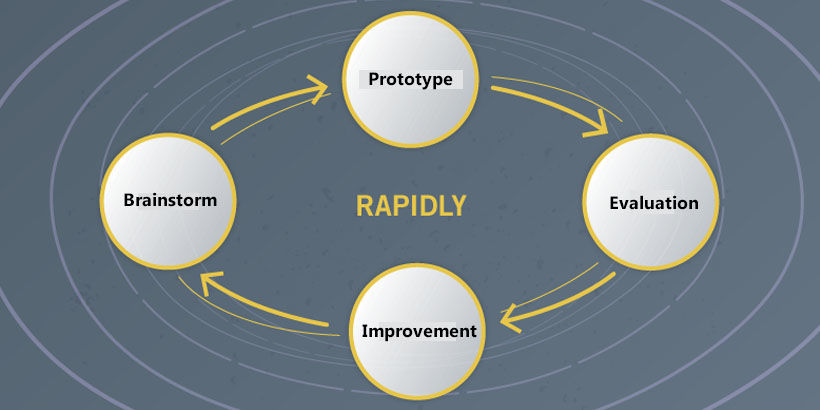

When 3D printing is used as the rapid prototyping process, it begins with taking a virtual style, after that the maker reviews information from CAD drawings and also puts down succeeding layers of materials, developing the physical model from a collection of cross-sections. The process of rapid prototyping is as following:

Brainstorming -> Prototyping -> Evaluation -> Improvement

Please note that rapid prototyping is not equal to 3D printing, what’s the distinction between rapid prototyping and 3D printing? 3D printing is the procedure to produce a rapid prototype, the prototyping often regarded as the outcome or output, which can be finished via different producing processes, not only 3D printing.

Approaches of rapid Prototyping

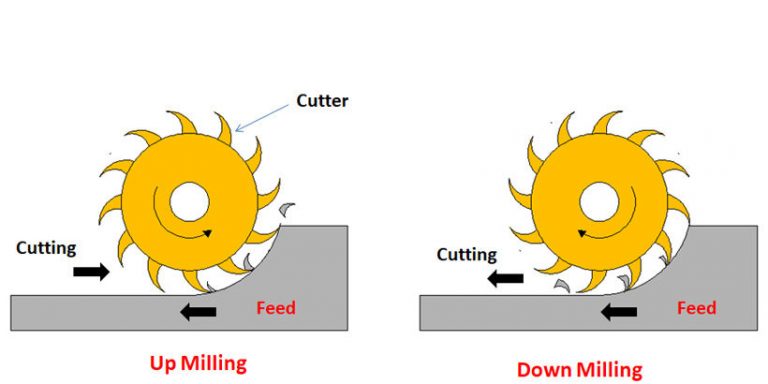

Additive manufacturing techniques are most typical for rapid prototyping, even more, standard processes can likewise be used to create prototypes, such as subtractive methods: milling, grinding, transforming or high-speed machining; and also compressive techniques: spreading compressive sintering or moulding. Select a correct fast prototyping innovation based on the speed, price, strategy growth stage, material compatibility, and fidelity degree.

Types of rapid prototyping methods (additive manufacturing as well as other techniques).

- Stereolithography (SLA).

- Selective laser sintering (SLS).

- Direct metal laser sintering( DMLS).

- FusedDeposition Modelling (FDM).

- Binder jetting.

- Poly jetting.

- 3D printing (3DP).

- SelectiveLaser Melting (SLM) or Powder Bed Fusion.

- Laminated object manufacturing (LOM) or Sheet Lamination.

- Digital Light Processing(DLP).

- CNC Machining Prototyping.

- Vacuum casting.

- Investment casting.

Pros and Cons of Rapid Prototyping

Pros of rapid prototyping

- Safe. You can collaborate with managers, designers, individuals, and also various other developers, there are much more chances to uncover the most effective idea. Evaluating the prototype with real customers will certainly ensure success as well as stay clear of various defects.

- Quick. Compared to the traditional approach, rapid prototyping can conserve much time by finishing the layout and test in a short cycle. If the design completely fulfils the demands, you can begin the complete manufacturing of the part as well as if it has problems, deal with versions or discard the concept entirely.

- Cost-saving. Because rapid prototyping conducts the screening at a real onset, which conserves a quantity of growth expense prior to back-end product design.

- Creative thinking. A rapid prototype is extra for boosting imagination as think less and ideate faster.

Cons of rapid prototyping

Rapid prototype likewise has its downsides. In enhancement, when all the attention is on the model, might cause not enough analysis of the full job.

Rapid Prototyping Services

DEK can provide precision CNC machining services and online rapid prototyping services to bring your CAD files as well as styles to life at high speed and also accuracy. Fast to get a free quote for your drawings and start in your jobs.