Guide to Rivets and their applications

Rivets are just one of the most timeless bolts made use of in mechanical applications, their permanency and also firmness make them different from various other fastening elements. To match varying needs, there is a variety of rivets made for various styles. What are the different sorts of rivets as well as their uses? Below are intros per group of the rivet with information entailing their building, setup, and applications.

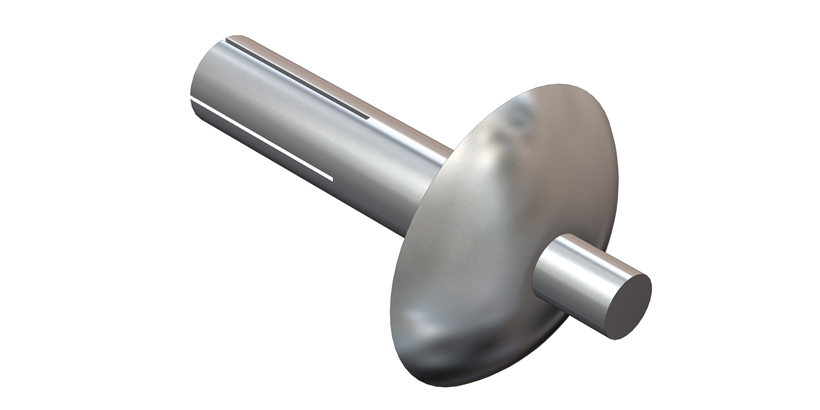

What is Rivet?

A rivet is a type of mechanical fastener that used to connect or setting up parts completely through distinct mounting methods. It includes a smooth round shaft gotten in touch with a direct one end, the head has a bigger size than the shaft. Exactly how does a riveting job? Put the rivet right into a drilled hole in the product being attached, make the smaller end flawed utilizing exterior influence to flatten this end as well as protect it firmly. As soon as the rivet is mounted, it will not fall off unless it is deliberately ruined. A rivet is additionally a CNC machined part that can be refined with aluminum, copper, and also even more materials.

Sorts of Rivets and Their Application

What are the different types of rivets and their applications? Generally used rivets including solid rivets, tubular rivets, blind rivets, drive rivets, split rivets, etc. Right here we detail the major rivets kinds and their appearance for much better recognition.

- Tubular rivets: likewise called semi-tubular rivets, its framework resembles strong rivets, the difference is tubular rivets have a partial opening at the tip. The style of the hole is for reducing the amount of pressure called for by rolling the tubular portion exterior. The needed force to apply a tubular rivet is 1/4 of that to use a strong rivet. The common applications of tubular rivets are lighting, brakes, ladders, binders, HVAC ductwork, mechanical items, and also electronic devices. The readily available materials are varying from steel, stainless, to brass, aluminum, and also copper.

- Split rivets: likewise referred to as bifurcated rivets, are a type of self-piercing rivets, split rivets have distinct styles, they have divided bodies or sets of legs on smaller-sized ends. The very best usages for split rivets are soft products, including timber, natural leather, or plastic.

- Blind rivets: additionally recognized as pop rivets, are tubular bolts consist of a rivet and a mandrel via the. Blind rivets can be separated right into common blind rivets, self-drilling blind rivets, self-tapping blind rivets, speed fastening blind rivets.

- Solid rivets: additionally referred to as rounded rivets, solid rivets are just one of the oldest bolts, have one of the most basic building and construction: a head and a shaft, which is deformed with a hammer or rivet weapon. A rivet compression or kinking device can likewise warp this sort of rivet. Solid rivets are driven utilizing a hydraulically, pneumatically, or electromagnetically activated squeezing device or perhaps a handheld hammer. Strong rivets are suitable for the applications where they call for high reliability as well as safety and security, consisting of aircraft structural parts (aluminum alloy rivet, titanium alloy rivet, nickel-based alloy rivet), bridges, cranes, developing frames (steel rivet), and contemporary recreations of middle ages shield, fashion jewelry and also steel style.

- Drive rivets: a kind of blind rivets that with a short mandrel from the head, where different from lots of blind rivets is that the mandrel of drive rivet is inculcated the rivet body to broaden the shank as well as make it hold the hole wall. Drive rivets are made use of to secure panels and also other comparable building functions to masonry walls, it does not need through-holes. Drive rivets are best for any type of purpose in which the hole does not pass through the whole sheet or panel.

There are much more forms of rivets offered. The flush rivets, additionally known as countersunk rivets, largely utilized on outside metal surfaces where they need a great look and removal of unnecessary aerodynamic drag. Their regular usages are the outside of the aircraft. And rubbing rivets, Oscar rivets, self-piercing rivets, etc. DEK CNC milling services and also CNC turning services can generate high-quality custom-made metal rivets and also other accurate machined components for your demands.