Guide to Setting a Lathe Cutting Tool

Placing the cutting point correctly as well as establishing a lathe cutting tool is critical to your CNC turning process, greatly affects the removal rate, cutting efficiency and surface finish. Today we’ll bring the actions for just how to set up lathe cutting tools easily.

What is a Turning Cutting Tool?

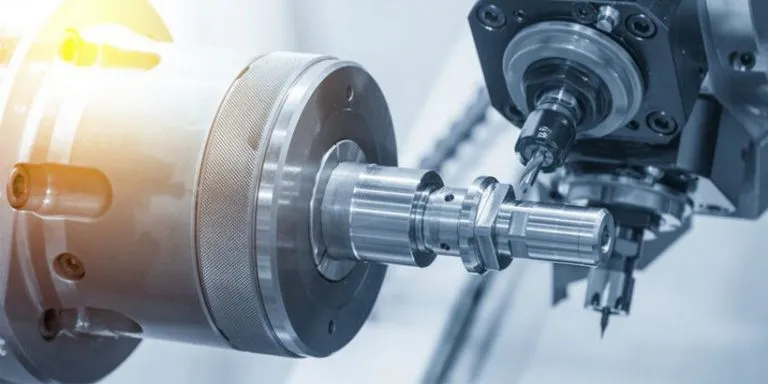

The turning cutting tool or cutter is a single-point tool, which typically held in a fixed setting on a lathe with the work surface turning around a turning axis, the non-rotary tool bit is made use of to get rid of materials from the work surface through one cutting edge relocating linearly. The lathe cutting tool generally includes a replaceable insert, seat, clamp, holder and screw, most turning work is completed with the insert, which employs a highly crafted composite structure and also coatings can reach high accuracy in CNC turning.

Just How a Cutting tool Installed on the lathe?

The lathe cutting tool is held in the device owner with tightening up the screws, as well as the device owner is attached to the device post with a quick-release lever, after that the device post is placed on the lathe maker a T-bolt.

Just how to Set up a Lathe Cutting Tool?

Turning is a metal cutting procedure that makes use of a single-point tool to create round surfaces oriented largely parallel to the workpiece axis, while the tool is fed into the part radially, axially or both ways all at once. Different tool holder styles and insert kinds allow turning, facing, grooving, threading, and also extra turning operations, here is a standard overview for establishing a cutting tool on the lathe to make certain a component be turned properly.

- Shut off the lathe machine, prepare a simple metallic ruler.

- Mount a cutting tool onto the tool holder or tool message safely and also set the holder perpendicular to the component.

- Load your cylindrical component in the chuck of a lathe, when you tighten up the chuck, turn the part with your hand gently, till it can not relocate any longer, to centre the turning component.

- Make the lathe carriage near to chuck end and make use of the crossfeed wheel to move the device towards the lathe component, get the leader pinched between the cutter and surface of the part firmly.

- Observe whether the ruler is totally upright if the leader is vertical, the device elevation is established correctly, you need to establish the securing nut of the readjusting knurled wheel to maintain the setting; if the leader is tilting to the right or left, then the cutter is put too high or too low, the idea of the lathe cutting tool is not according to the centre of the component. Release tool article cam and adjust the height wheel on the tool article to get it to the best height.

- Eliminate the cutter as well as install it once more longitudinally along the lathe axis, take the very first trial cut to examine if the tool is set at the right height. The appropriate setup will certainly leave a smooth encountering cut, while if the tool is not in the exact centre setting, there will be a little nib on the component.

- Take out the tool and established it up again perpendicular to the part if you require to transform a component along the axis. Do this for all the turning cutting tools that you prepare to use it turning your part or alter the tool.