Guide to Straddle Milling and Gang Milling

To attain various last profiles in machining, there are different CNC milling operations to match the application. Straddle milling, as well as gang milling, are using greater than one cutter in the manufacturing procedure, what grated parts do they produce? Right here we’ll describe the gang milling and also straddle milling, plus their distinctions and also some functioning tips.

What is Straddle Milling?

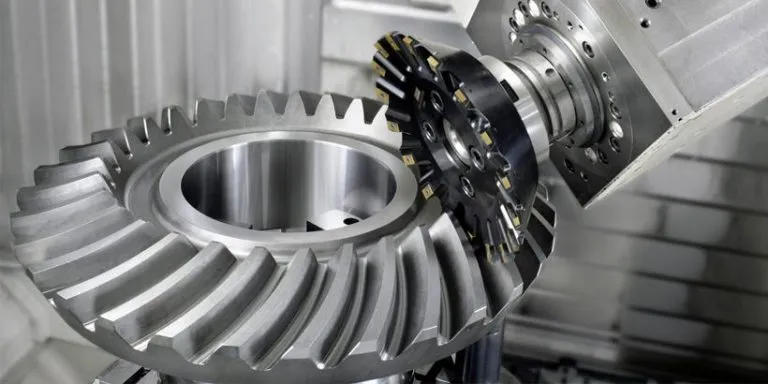

Straddle milling is a CNC milling operation in which 2 or more parallel vertical surfaces are machined in a single cut using 2 cutters divided by washers, shims, or spacers. For finishing straddle milling, two side milling cutters need to be mounted on the very same arbor, as well as set apart to make them straddle the work surface. Straddle milling uses sharp milling cutters on either side, it is feasible to device the items on opposite sides to parallel in a cut.

What sorts of cutters are used in the straddle milling procedure?

In a normal straddle milling, two side cutters are made use of. The cutter is a half-side or ordinary side milling cutter with straight or spiral teeth. Additionally, side milling cutters with staggered teeth can be used.

What is Gang Milling?

Gang milling is the machining process of 2 or more milling cutters used with each other. The cutters have the different or exact same sizes as well as are mounted on the arbor of the milling machine. In gang milling, all cutters can execute the same kind of operation, each cutter can also execute a various kind of procedure.

Distinction Between Straddle Milling as well as Gang Milling

In gang milling, lots of milling cutters are fastened to the arbor for fitting the shape of material space to be machined. Straddle milling is a special type of gang milling, typically creates 2 parallel vertical surface areas. There are usually 2 grating cutters placed on the arbor in straddle milling.