Guide to Thread Milling

Thread milling is a useful as well as versatile thread manufacturing remedy and also CNC milling process, particularly for big holes, the process has a tendency to be utilized mostly in lots of applications instead of touching, what are the benefits of thread milling? In this guide, we’ll discuss the troubles plus what is thread milling, its applications, types of tooling, how does a thread mill job, how to thread mill as well as even more.

Table of Contents

What is Thread Milling?

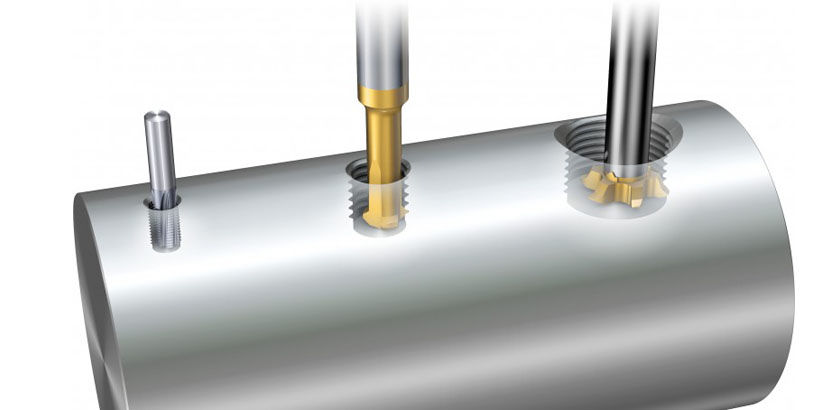

Thread milling is a procedure to cut threads at various sizes through the round ramping movement of a rotating device, the thread pitch is developed by the side motion in one change. The very same device can be utilized for both right-hand and also left threads, various thread resistance, various materials, as well as hole sizes, producing threads with high precision and also excellent surface finish.

Thread milling tools:

- Solid carbide thread mill: useful for smaller sized opening dimensions, a lot more pricey than indexable tools, however, can be cost-efficient.

- Indexable insert thread mill: not fit in holes that are 0.625 inches or much less in diameter.

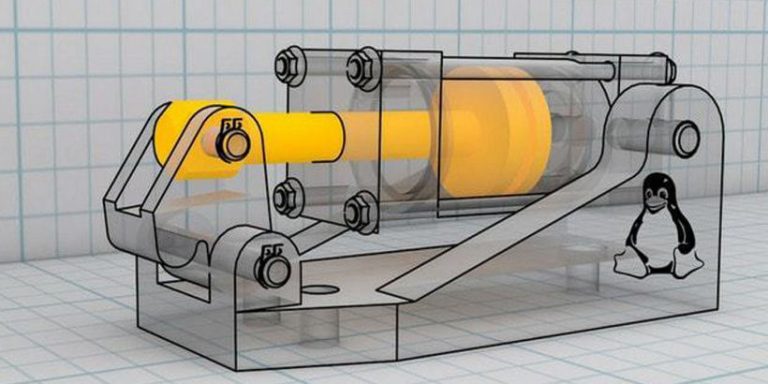

Just how Does a Thread Mill Job?

The thread milling process can utilize helical-interpolation device paths to change touching and also the thread mill looks similar to faucets, however, the impact is various. When the thread mill does the round movement, it needs to move in the direction of the top of the opening or relocate one thread pitch along the Z-axis of machines, for producing a thread.

Thread Milling Applications

Thread milling is an ideal machining procedure in adhering to applications or needs:

- Thin-walled parts

- Asymmetric/non-rotating parts

- Machining materials generate high reducing force as well as simple to trigger chip discharge troubles

- Calling for to decrease device inventory

- Unpredictable component setups

- As an option to tapping

- Adjust the tolerance of the thread

- Cut numerous odd thread sizes with a solitary tool

- Back chamfer the hole

The Distinction & Advantages of Thread Milling

Compared to tapping, why choose the thread milling process?

- Thread milling is extra functional to make a broad range of threads, left-hand or ideal, internal or outside, solitary or numerous.

- Thread milling can deal with more products, whether it’s hard or soft metals, heat-treated or difficult alloys.

- Thread milling produces pipe threads conveniently without producing the bothersome fibrous chips generated in the tapping procedure.

- Thread milling can attain a far better Threadtop quality and smoother surface than touching.

- Thread milling procedure is simpler to be done than tapping on CNC machines because of calls for lower cutting force.

- It is not required to set appropriate hole size in the thread milling procedure

- Tiny faucets simple to damage throughout the tapping process, clearing remnants is hard and time-consuming, which might cause scrapped component.

Just How to Thread Mill?

Select a proper quality device

High quality and suitable thread milling tool is necessary to avoid failing as well as troubles throughout the process, you can choose some certified tooling suppliers and compare their benefits as well as downsides, and select the one closest to your demand. Before that, you require to understand the kinds of thread mills (Helical flute thread mills, Straight flute thread mills, Solitary account thread mills, Indexable insert thread mills, Solid carbide thread mills, and so on) as well as specs of those thread milling cutters (Single form, Tri-form, as well as Multi-form), like diameters.

Apply for several radial passes

Different the thread milling procedure into numerous radial passes can accomplish higher quality, boost the Thread tolerance, guarantee safety and security and stay clear of tool damage in difficult-to-machine materials, in addition, to make it suit in difficult applications, like unstable conditions and also lengthy overhangs.

Choose chip damage and removal method

Apply correct tool or approach to damage and also evacuate chips timely, reducing liquid and also lube can be taken into consideration, stay clear of chip recutting, conserve time as well as assure the tolerance of thread.

Determine tool path

Left or right-hand threads are depending upon the chosen tool path. Which one is more suitable for you? Pick the extra reliable one according to your experience.