Summary of Distinction Between 2D and 3D CAD Drawing

CAD files are typically made use of in mechanical layout and also production, which brings automation and also innovation to lots of appropriate industries. A lot of the manufacturers have actually taken on the 3D CAD, if you are trying to choose a much better option in between 2D vs 3D CAD, have a look at the distinction between 2D as well as 3D CAD illustration, we’ll likewise enter into the advantages of 3D CAD over 2D, assist you locate the ideal option.

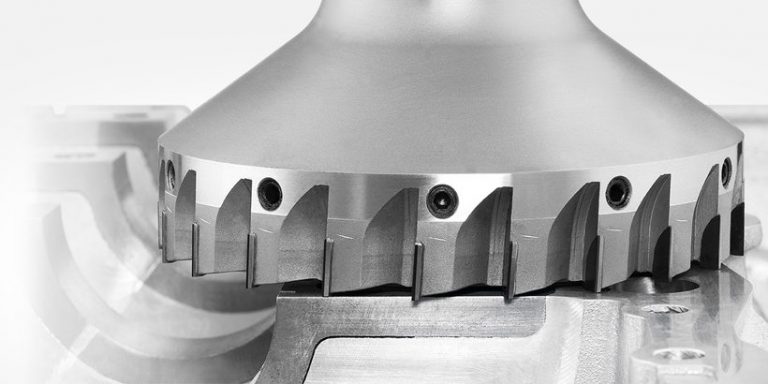

Why CAD is Utilized in Manufacturing and also CNC Machining?

In the past, developers need to make use of paper, pencils, and various other basic devices to compose their part attracting, with the development and also application of CAD software, it changed the method of layout and also produced in the manufacturing market, as well as quickly reached the CNC machining process, it makes the drafting more exact and computerized.

Making use of CAD data, you can check out each information of the component, even the internal functions, it enables the 3D model to be amplified and also rotate on any type of axis, to recognize the element much better. What’s even more, CAD makes it possible to replicate the activity of a work surface via CNC manufacturing procedures.

Difference Between 2D as well as 3D CAD Illustration

Interpretation

2D CAD is a two-dimensional Computer-Aided Design, 3D CAD is a three-dimensional Computer-Aided Design.

Expression

2D is a display of size as well as elevation on a plane without deepness. While 3D is specified as 3-dimensional drawings or versions they explained items with depth, elevation, and also size.

Geometry

2D CAD illustration is connected to rectangular shape, square, triangle, polygon, etc., as well as 3D illustration, includes a cylindrical tube, dice, ball, pyramid, prism, and also even more.

Measurement/Unit

2D illustrations are usually determined in square devices like centimeters ², while 3D dimension consists of cubic unit centimeters ³, and quart liters.

Elements

In the 2D CAD system, items, as well as engineering style drawings, are typically regarded as a collection of geometric components such as points, lines, circles, arcs, and so on, rely upon the geometric models. The core of the 3D CAD system is the 3D model of the item, which represents the actual shape of the product on the computer. The model consists of different details regarding the factors, lines, deals with, and entities of the product geometry.

Discussion

Because the 2D CAD drawings are plain, developers need to understand how the final product looks plainly, this might be tough for individuals that do not with a technological background. While with the 3D CAD version, we can see the final product, most people can comprehend the style. It’s also much easier to describe the item as well as show in presentations to consumers as well as workers with a 3D version.

Advantages of 3D CAD over 2D

In general, the advantages of 3D CAD innovation and also software than 2D CAD for mechanical style are as follows:

Enhance product top quality and technological content

With the support of 3D CAD innovation, modern-day mechanical production utilizes sophisticated style methods to enhance the degree of layout and also make sure the high quality of items, involves optimization, virtual style of items, finite aspect stress and anxiety analysis, activity simulation, and so on. The mechanical item is incorporated with infotech. Additionally, CAD and CIMS are also related to organizing manufacturing, which promotes the new growth of the mechanical product style.

Help with the setting up of components extra user-friendly and also intuitive

CAD software makes 3D style can show the architectural functions of components strongly and also intuitively. When developing components, developers can use 3D entities or perhaps 3D entities with fairly complex restraints to layout, recognize the simulation assembly as well as simulation operation in the layout stage, so as to make the layout closer to the actual procedure.

Reduce design time as well as enhance the effectiveness

In the procedure of variable and also the parametric layout of 3D CAD, parts can be altered according to the adjustment of framework dimension to attain the suitable result. In this method, 3D CAD technology can aid designers to decrease a whole lot of workloads, lower working time, as well as enhance working effectiveness by 3-5 times.

Promote CAD/CAM assimilation

In the traditional style, CNC machining is based on the drawings created by CAD, so it is unpreventable that there are 2 sets of the very same component information in CAD and CAM, which is easy to bring about monitoring complication. Since 3D style can recognize the combination of CAD/CAM, it indicates the 3D CAD modern technology supports the entire procedure of the item from layout to manufacturing. With detailed integration as well as details circulation automation, CAM can straight acquire the info of CAD for handling, which can make certain that the products obtained by machining are precisely constant with the design.