Summary of Form Milling

A milling machine can cut material to various outcomes making use of various devices. In this write-up, we’ll talk about what is form milling. Follow us to learn more about the advantages of kind milling and also details of the form cutter, entailing its kinds, makes use of, as well as configurations.

Table of Contents

What is Form Milling?

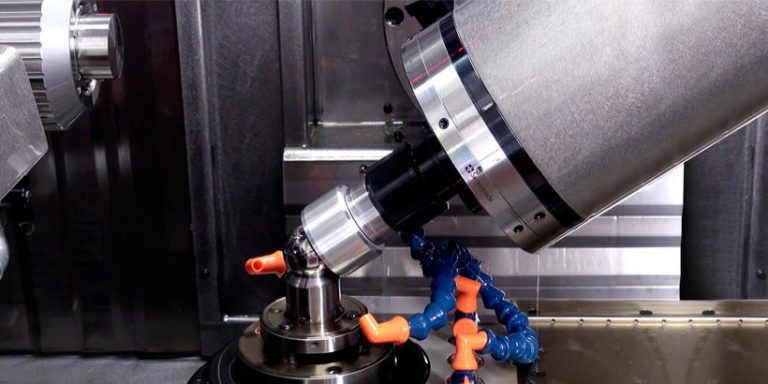

Form milling is a sort of CNC milling operation of creating irregular shapes consisting entirely of curves or of contours and also straight lines, at a solitary cut with type milling cutters. The special uneven shape can be concave, convex, or of any other form. The machining speed of kind milling procedure is 20 to 30 % lower than that in plain milling.

What is Form Milling Made Use Of for?

Typical form milling operations are used to grating half-round recesses, grains, and also quarter-round spans. Elaborate patterns or numerous intricate surface areas on CNC milling parts in a cut can be recognized in form milling, such as helical equipment.

Virtues of Form Milling

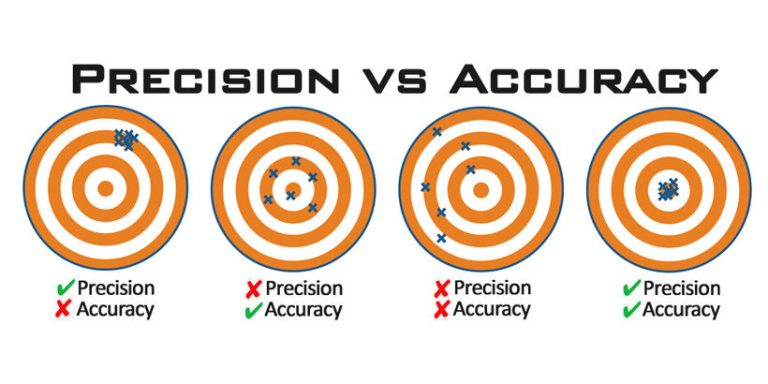

Despite the fact that the type of milling device is not inexpensive, yet it is a crucial contributor in time-saving, keeping precision as well as decreasing total expense, which is beneficial to your firm.

Among the largest benefits of type milling and where you utilize it one of the most is when we enter into circumstances where a hard detail to mill or produce sometimes, if you have actually obtained different radius and also every little thing, we can combine that device and simply encountered as well as mill everything at the same time. You have actually got a scenario where they are going to do an angle, show up a level face, and then do o radius, which will generate a device that can finish all at once. When you get an airplane component in an odd shape and also wish to put a span, what we can do is to construct a type device with that said radius.

There are significant financial savings making use of a radius form device for milling. You won’t make use of form milling when you enter into the scenario where you have actually got a shape to reduce and also you can get that with a fairly good-sized end mill to find in as well as cut the contour. A cutter to do that form, it’s going to be a great deal stouter cutter and also they’ll just come in as well as clip it in one pass, where you can get a big enough diameter device that can do the milling, you do not need to have a kind tool.

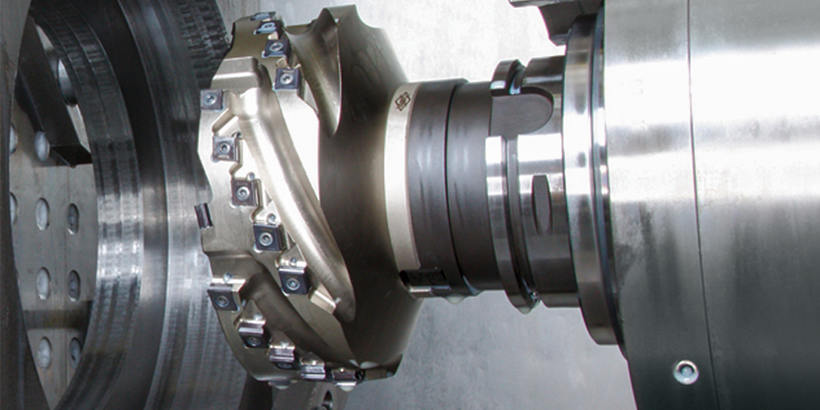

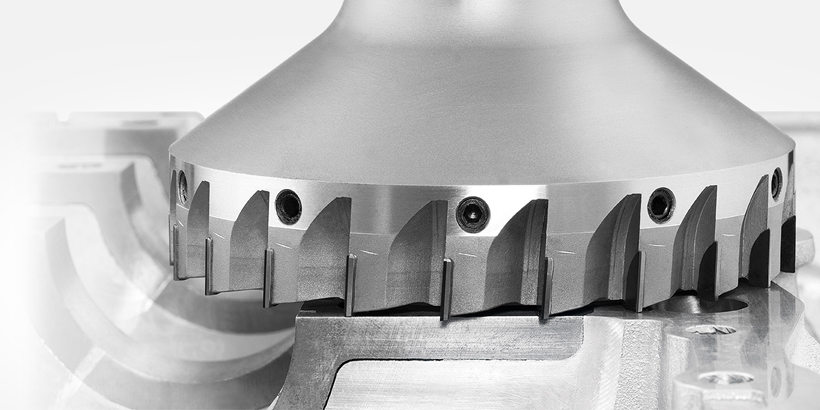

What is Form Milling Cutter?

Form milling cutters have not a standard definition, it’s made use of for producing 2D and also 3D shape surface areas. There are different kinds of cutters in different forms, arrangements, and for various applications. The form cutters can be made from alloy steel, solid carbide, brazed carbide, and HSS. The usual types of form milling cutters include concave, convex, and also corner rounding milling cutters. Form milling cutters can likewise be available in the straight gash, spiral gash, serration form, special kind happy, easy keyway bores, as well as complex centers & shanks.

The teeth of the form milling cutter have a form that corresponds to the profile of the surface area to be generated. The form milling cutter can be applied in great deals of regular CNC milling as well as machining procedures, consisting of interior sphere nut track milling, outside rotary milling of threads on difficult-to-turn materials, inner thread type milling on neck ring mold and mildews, interior rotary recess type milling, groove milling, complete distance milling, chamfering, face milling and also even more. Picking a flexible kind cutter can not just enhance your efficiency, yet additionally, enhance the ability.