The Future Of Additive Manufacturing In Mechanical Engineering

Hey there! As a mechanical engineer, I am always keeping an eye out for the latest technology that can improve our industry.

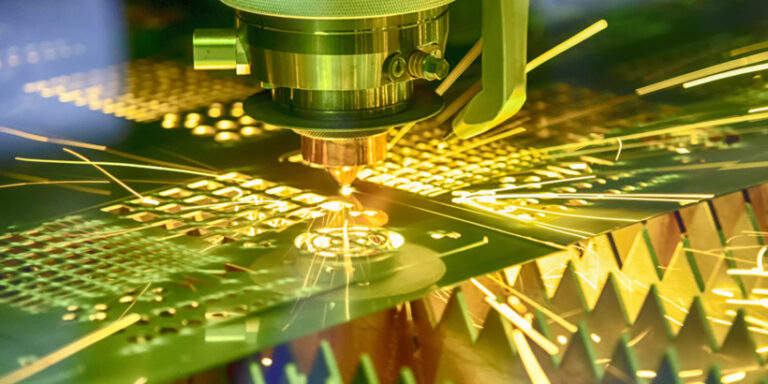

One such technology is additive manufacturing, also known as 3D printing. Additive manufacturing has already made significant strides in various fields, and with advancements being made every day, it’s exciting to think about what the future holds.

In this article, we’ll take a closer look at the role of additive manufacturing in mechanical engineering and how it’s poised to transform the way we design and produce parts.

From reducing production time and costs to creating complex geometries that were previously impossible to make – let’s dive into the potential of additive manufacturing in mechanical engineering!

Basics Of Additive Manufacturing

Did you know that the global additive manufacturing market size is expected to reach $23.33 billion by 2025? That’s a huge number, and it highlights just how much potential there is for this technology in mechanical engineering.

At its most basic level, additive manufacturing involves building objects layer-by-layer using digital models as a guide. This makes it possible to create complex geometries and custom designs in ways that would be impossible with traditional manufacturing techniques. Of course, material selection plays a crucial role in determining what can be built via AM, but advances in materials science are opening up new possibilities all the time.

One of the biggest hurdles to widespread adoption of AM has been infrastructure costs – setting up an effective printing facility requires significant investment in equipment, software, and personnel training. However, as more companies invest in these capabilities and develop best practices for scaling production, we’re likely to see those costs come down over time.

Ultimately, the basics of additive manufacturing offer exciting opportunities for innovation across multiple industries – from aerospace to healthcare – and I’m excited to explore where this technology will take us next.

Benefits Of 3d Printing In Mechanical Engineering

One of the most significant benefits of additive manufacturing in mechanical engineering is cost savings. By using 3D printing technology, manufacturers can save on material and labor costs by reducing waste materials and minimizing assembly time.

Additionally, with a reduced need for traditional machining methods, companies can further reduce their expenses while still creating high-quality products.

Another advantage of 3D printing is its ability to save time in the design process. With traditional manufacturing methods, designing and prototyping a new product could take weeks or even months.

However, with 3D printing technology, engineers can produce multiple iterations quickly and efficiently until they reach the desired outcome.

By utilizing these two key advantages – cost savings and time-saving – manufacturers are able to create more complex products at a faster rate than ever before.

As such, it’s no surprise that many companies are turning towards additive manufacturing as an innovative solution to achieving better results while also saving money and time.

Challenges And Limitations

As exciting as the future of additive manufacturing is, it’s not without its challenges and limitations. Like any emerging technology, there are still hurdles to overcome before we can fully unlock its potential.

One major challenge is material selection – while 3D printing has come a long way in terms of being able to print with a variety of materials, there are still some that present difficulties. Additionally, there’s the issue of the skills gap – engineers need specialized training to be able to design for additive manufacturing effectively, and right now there aren’t enough people with those skills.

But despite these challenges, I’m optimistic about the future of additive manufacturing in mechanical engineering. There are already so many incredible things being done with this technology, from creating lighter and more efficient parts for aerospace applications to custom prosthetics that fit perfectly on each patient.

If we continue to invest in research and development, push boundaries and explore new frontiers, I believe we’ll see even more amazing breakthroughs in the years ahead. The journey won’t always be easy or straightforward, but it will certainly be worth it.

Application Areas Of Additive Manufacturing

When it comes to additive manufacturing, there are a variety of application areas that can benefit from this revolutionary technology.

One key aspect is material selection. With the ability to use a wide range of materials such as metals, plastics, and even ceramics in 3D printing, engineers have more options when designing their products. This enables them to choose specific materials based on their properties and characteristics which will ultimately result in better performance and durability.

Another important factor is process optimization. By using advanced software tools and simulation techniques, engineers can optimize the entire production process from design all the way through to final product testing. This allows for greater efficiency and accuracy during fabrication which translates into lower costs and higher quality end-products.

Ultimately, additive manufacturing has opened up new doors for mechanical engineering professionals who are now able to create complex geometries with ease while also improving upon traditional methods of production.

Different Types Of Additive Manufacturing Technologies

Just like how the branches of a tree lead to its sturdy trunk, understanding the application areas of additive manufacturing is crucial before delving into its various types.

Now that we have established the former, let’s explore the different technologies used in this field.

One important aspect of additive manufacturing is material selection choosing which materials will work best for specific projects and products.

The process optimization is also essential as it helps streamline production processes, saving time and resources while maintaining quality output.

By having an in-depth knowledge of these technologies, engineers can create revolutionary designs that were once impossible with traditional methods.

Additive manufacturing has already made significant strides in industries such as aerospace, automotive engineering, and healthcare, among others.

There’s no doubt that this technology will continue to shape the future of mechanical engineering by providing efficient solutions without compromising on design or functionality.

Design Considerations For 3d Printing

When it comes to 3D printing, there are several design considerations that need to be taken into account.

Firstly, complex geometries can often be achieved with additive manufacturing that aren’t possible through traditional methods. This allows for more intricate and unique designs to be created.

Secondly, material selection is crucial as different materials have varying levels of strength, durability, flexibility, and other properties that may affect the final product’s performance. It’s important to choose a material that fits the specific requirements of your project.

Additionally, print orientation and support structures should also be considered as they can impact the quality and accuracy of the final product.

Finally, post-processing techniques such as sanding or painting can help enhance the aesthetics of the printed part while improving its functionality at the same time.

By keeping these design considerations in mind, engineers can take full advantage of what additive manufacturing has to offer and create innovative solutions for their projects without being limited by traditional manufacturing methods.

Future Trends In Additive Manufacturing

Hold onto your hats because the future of additive manufacturing in mechanical engineering is going to blow your mind! With emerging technologies constantly being developed, we can expect even more incredible advancements in this field.

The possibilities for production optimization are endless with the ability to create complex designs and shapes that were once impossible through traditional methods. As companies continue to invest in research and development, we’ll see faster printing speeds, improved materials, and increased precision.

It’s safe to say that the future looks bright for additive manufacturing and it’s only a matter of time before it becomes an essential part of every engineer’s toolkit. So buckle up and get ready for a wild ride into the exciting world of 3D printing!

Conclusion

In conclusion, the future of additive manufacturing in mechanical engineering is incredibly exciting. As someone who has been following this technology for years, I can confidently say that we are on the verge of a major shift in how we design and produce mechanical parts.

The benefits of 3D printing in mechanical engineering are undeniable. From faster prototyping to more complex geometries to reduced waste, there are so many ways that additive manufacturing is making our lives as engineers easier and more efficient. Of course, there are also challenges and limitations to consider – but with each passing year, these hurdles become smaller and smaller.

Looking ahead, it’s clear that additive manufacturing will continue to play an increasingly important role in mechanical engineering. With new technologies emerging all the time and companies investing heavily in research and development, the possibilities are truly endless.

In fact, I wouldn’t be surprised if one day soon we see entire factories powered by 3D printers! Okay okay…maybe that’s a bit of hyperbole – but you get my point. The sky really is the limit when it comes to additive manufacturing.