The Importance Of Materials Science In Manufacturing

As someone who enjoys using technology and consumer products, it is easy to overlook the intricate processes involved in manufacturing. However, materials science plays a crucial role in bringing these products to life.

From developing sustainable packaging solutions to creating high-performance materials for aerospace applications, the field of materials science has revolutionized modern manufacturing.

The importance of materials science cannot be overstated when it comes to improving product performance, durability and safety. With emerging technologies such as 3D printing and nanotechnology, we are only just beginning to scratch the surface of what is possible with advanced material engineering.

In this article, we will explore why materials science is critical for successful manufacturing and how advancements in this field can benefit both consumers and businesses alike.

Table of Contents

Sustainable Packaging Solutions

Have you ever thought about the amount of waste we produce, especially in terms of packaging materials?

As someone who cares deeply about sustainability, I have been exploring ways that manufacturing can contribute to reducing waste. One solution is sustainable packaging – this involves using materials and design techniques that are environmentally friendly, cost-effective, and practical for businesses.

By adopting a circular economy approach where production processes minimize waste and enhance resource efficiency, manufacturers can reduce their environmental impact while still delivering high-quality products.

In this section, we will delve into some exciting developments in sustainable packaging solutions that could revolutionize the industry.

Enhancing Product Performance

So, sustainable packaging solutions…who needs ’em anyway? I mean, sure we all want to save the planet and reduce waste, but at what cost to our products’ performance?

That’s where materials science comes in. By enhancing product performance through innovative material choices, we can have our cake and eat it too (figuratively speaking, of course).

Using advanced materials like composites and nanomaterials, we can achieve enhanced efficiency without sacrificing quality or durability. Plus, with reduced waste thanks to better manufacturing processes and recycling techniques, we can feel good about doing our part for the environment while still delivering top-notch products.

- Advanced composite materials offer lighter weight options that maintain strength and durability.

- Nanomaterials provide improved electrical conductivity for more efficient energy transfer.

- Innovative manufacturing techniques such as 3D printing significantly reduce waste by precisely producing only necessary components.

By prioritizing the importance of materials science in manufacturing, not only can we improve our products’ performance and reliability, but also make a positive impact on the world around us.

So let’s embrace these new technologies and create a brighter future for ourselves and generations to come.

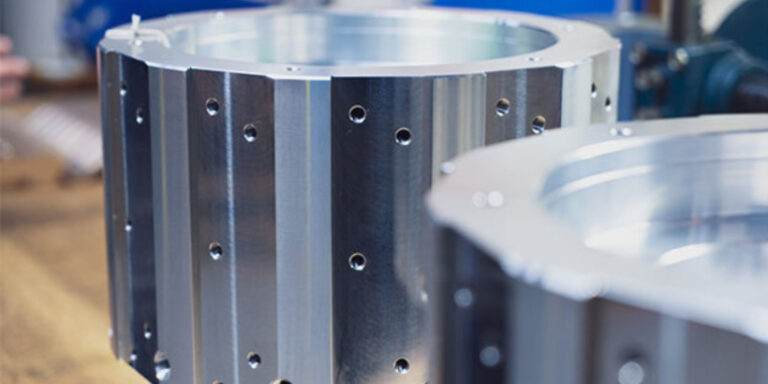

Increasing Product Durability

When it comes to manufacturing, one of the most important factors is product durability. Consumers want products that will last for as long as possible, and manufacturers want to ensure that their reputation remains strong by producing high-quality goods.

That’s where materials science comes in – with advanced coatings and polymer composites, manufacturers can create products that are not only strong but also resistant to wear and tear. Advanced coatings provide an extra layer of protection against corrosion and abrasion while ensuring a smooth surface finish. Polymer composites, on the other hand, offer superior strength-to-weight ratios compared to traditional materials such as steel or aluminum.

By incorporating these technologies into their production processes, manufacturers can increase the lifespan of their products significantly. This not only benefits consumers who get more value for their money but also helps reduce waste by decreasing the need for replacements or repairs.

Ultimately, investing in materials science is crucial for any manufacturer looking to stay ahead of the competition and meet consumer demands for longer-lasting, higher quality goods.

Improving Product Safety

As we know, safety is a top priority for manufacturers and consumers alike. Fortunately, materials science has made significant strides in improving product safety through improved testing techniques and reduced waste in the manufacturing process.

With these advancements, products can be thoroughly tested to ensure they meet strict safety standards before hitting the market. This not only gives consumers peace of mind but also allows manufacturers to avoid costly recalls or lawsuits due to faulty products.

Additionally, by reducing waste during production, companies are able to minimize their environmental impact while simultaneously saving money on resources.

It’s clear that investing in materials science research and development will continue to have a positive impact on product safety for years to come.

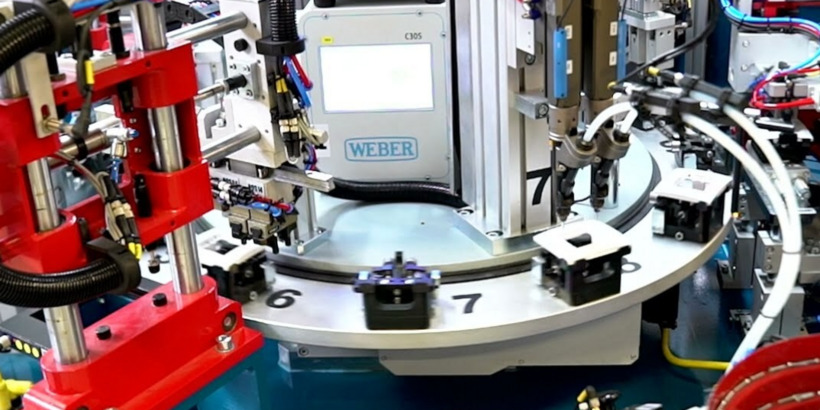

Leveraging 3d Printing

I think 3D printing is an incredibly interesting and useful technology, but it’s important to understand its advantages and limitations. For one, 3D printing allows for faster production of complex parts in a cost-effective manner, but there are still some materials that can’t be used with 3D printing. And there are so many potential applications for 3D printing, from creating customized parts for cars to printing prosthetics for amputees.

Advantages Of 3d Printing

As someone who has always been interested in the intersection of technology and manufacturing, I can confidently say that 3D printing is a game-changer.

One of the major advantages of this new technology is its ability to customize shapes and designs quickly and easily.

With traditional manufacturing techniques, creating unique products would often require costly and time-consuming tooling changes.

However, with 3D printing, businesses can produce custom parts or prototypes almost instantly, allowing for greater flexibility and innovation.

Another significant benefit of 3D printing is its potential to reduce waste.

Traditional subtractive methods like CNC machining typically result in high levels of scrap material being generated during production.

In contrast, additive manufacturing processes like 3D printing only use the exact amount of material required to build each part, significantly minimizing waste output.

Overall, it’s clear that leveraging 3D printing technology can bring numerous benefits to modern-day manufacturing practices – from reducing costs and increasing efficiency to unlocking new design possibilities making it an essential consideration for any business looking to stay ahead in today¡¯s competitive market.

Limitations Of 3d Printing

But as with any technology, 3D printing also has its limitations. While it offers great potential for customization and waste reduction, there are still some challenges that need to be addressed.

One of these is the limited range of materials that can currently be used in 3D printing. Although new types of filaments and powders are being developed all the time, many traditional manufacturing materials like metals or ceramics remain difficult or impossible to print using current technology.

Another limitation is energy efficiency depending on the type of printer and material used, 3D printing can consume significantly more energy than other manufacturing methods.

Despite these challenges, however, I believe that the benefits of 3D printing far outweigh the drawbacks – both for businesses looking to streamline their production processes and individuals seeking creative expression through novel design possibilities.

Applications Of 3d Printing

Now, let’s talk about the exciting applications of 3D printing.

One major advantage is its ability to facilitate rapid prototyping and design automation.

Companies can quickly create prototypes and iterate designs without having to wait weeks or months for traditional manufacturing methods.

This allows businesses to bring products to market faster while reducing costs.

Additionally, designers can use 3D printing to explore new shapes and structures that were previously impossible with conventional manufacturing techniques.

The possibilities are endless, from creating intricate jewelry pieces to building entire houses using large-scale printers.

With so much potential, it’s clear that leveraging 3D printing will continue to revolutionize various industries in the years ahead.

Optimizing Nanotechnology

Now that we’ve explored the potential of 3D printing, let’s dive into another exciting field within materials science: nanotechnology.

At the nanoscale level, engineers can manipulate matter to create new materials with exceptional properties, from stronger and lighter metals to super-stretchy fabrics. Nanoscale engineering is already being used in a range of industries such as electronics, medicine, and energy production.

Another fascinating application of nanotechnology is quantum computing, where tiny particles are harnessed to perform complex calculations at unprecedented speeds. As these technologies continue to evolve and mature, they have enormous potential for revolutionizing manufacturing processes and creating products that were once thought impossible.

By optimizing nanotechnology, we can unlock an entirely new realm of possibilities in material design and production methods.

Benefiting Consumers And Businesses

Did you know that according to a study conducted by Deloitte, 79% of consumers are willing to pay more for products made with sustainable materials? This is just one example of how advancements in materials science can benefit both businesses and consumers. By utilizing new materials and manufacturing techniques, companies can reduce costs while also minimizing waste. For instance, implementing closed-loop systems where waste from one part of the production process becomes raw material for another can significantly cut down on waste and save money in the long run. Consumers benefit from these advances as well, through increased product durability, improved safety features, and reduced environmental impact. It’s clear that investing in materials science isn’t just good for business – it’s good for everyone involved.

| Benefit | Explanation | Example |

|---|---|---|

| Reducing Costs | Utilizing sustainable materials and manufacturing processes can lead to decreased expenses over time. | A company switching from plastic packaging to biodegradable alternatives saves money on disposal fees |

| Minimizing Waste | Implementing closed-loop systems or recycling programs reduces excess waste generated during production. | An automotive manufacturer reuses scrap metal from factory floors in future vehicle components. |

Conclusion

In conclusion, I firmly believe that materials science plays a pivotal role in the manufacturing industry. Without it, we would not have sustainable packaging solutions or products with enhanced performance and durability. Safety is also paramount in product design, and materials scientists work tirelessly to ensure that their creations meet strict safety standards.

Moreover, 3D printing has revolutionized the way we manufacture goods today. It allows us to create complex shapes and structures quickly and efficiently while optimizing material usage.

Nanotechnology has also opened up new possibilities for enhancing material properties and improving product designs further.

Overall, consumers benefit greatly from advancements in materials science as they get access to better quality products with improved functionality and reliability. Businesses can leverage these innovations to gain a competitive edge by introducing unique features into their offerings that set them apart from competitors.

As the saying goes, ‘you’re only as good as your tools,’ which rings true for manufacturers who rely on materials science to develop high-quality products that meet consumer demands.