The Importance Of Quality Control In Manufacturing

Hey there! Have you ever bought a product that didn’t work as advertised or broke after just a few uses? It’s frustrating, right?

Well, one of the main reasons this happens is because of poor quality control in manufacturing.

Quality control is essential for any manufacturing process to ensure that products are produced consistently and meet customer expectations.

Without proper quality control measures in place, manufacturers run the risk of producing faulty goods, which can lead to unhappy customers, lost sales, and damage to their reputation.

In this article, we’ll explore why quality control is so important in manufacturing and how it benefits both manufacturers and consumers alike.

So let’s dive in!

Defining Quality Control

Have you ever received a product that didn’t meet your expectations? Maybe it was faulty or had defects that made it unsafe to use.

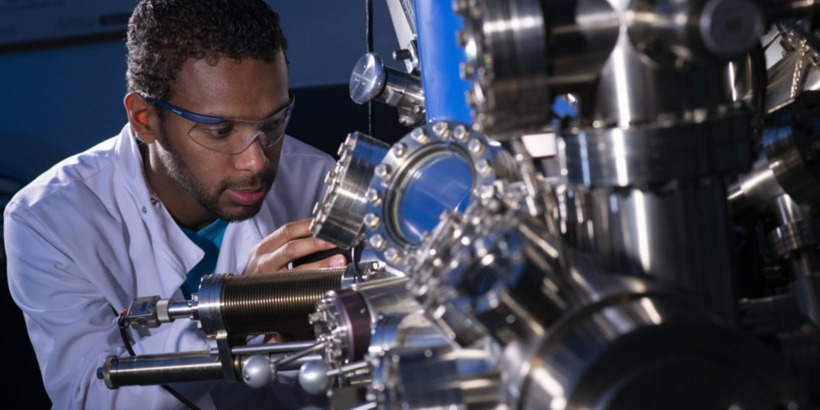

Well, this is where quality control comes in. Quality control refers to the process of ensuring that products are manufactured at an acceptable standard and meet customer requirements. It involves inspecting products for errors, identifying flaws, and correcting them before they reach consumers.

By implementing quality control measures, manufacturers can prevent costly mistakes and ensure cost efficiency by reducing waste and rework. Moreover, quality control also ensures improved safety for customers as defective products could pose serious risks to their health and well-being.

Benefits Of Quality Control

Now that we have defined quality control, let’s talk about why it is so important.

Implementing a strong quality control program can lead to significant cost savings in manufacturing. By catching defects early on and preventing them from reaching the end customer, companies can avoid costly recalls and rework expenses.

In addition, ensuring high-quality products also leads to increased customer satisfaction, which can translate into repeat business and positive word-of-mouth marketing. When customers trust that they are receiving reliable and consistent products, they are more likely to become loyal brand advocates.

Ultimately, investing in quality control not only benefits the bottom line but also helps build long-term relationships with customers.

Types Of Quality Control

Now that we understand the significance of quality control in manufacturing, let’s take a closer look at its different types.

So, what are the various methods of Quality Control?

To start with, there are three primary types: Statistical Process Control (SPC), Inspection, and Total Quality Management (TQM).

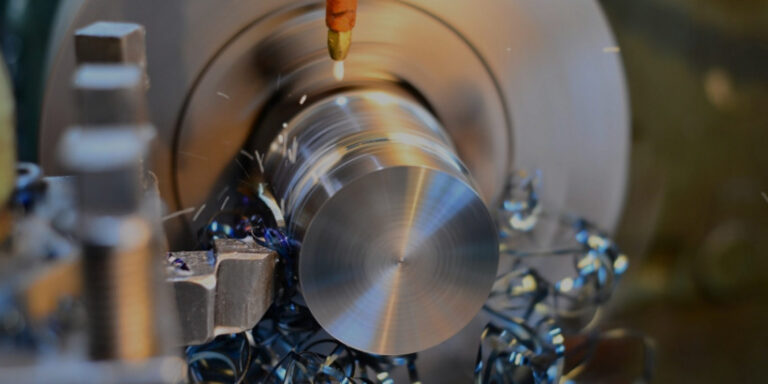

SPC is all about monitoring and controlling a process while it’s still ongoing to ensure high-quality products.

On the other hand, inspection involves examining every product carefully before approving them for distribution or sale.

TQM is more comprehensive as it encompasses an organization-wide approach towards maintaining quality standards.

These methods provide cost effectiveness by detecting defects early on during production rather than after releasing faulty products into the market.

Additionally, they emphasize statistical analysis to help identify trends and areas needing improvement continually.

By using these techniques effectively, manufacturers can improve their processes’ efficiency and reduce costs incurred due to rework or scrapping defective products.

Quality Control Processes

Now that we understand the significance of quality control in manufacturing, let’s delve deeper into the processes involved.

Quality control processes refer to preventive measures put in place to ensure that products meet specific standards and are free from defects.

One of the critical steps involved is risk assessment whereby potential risks that may affect product quality are identified and addressed before production begins.

The process also involves continuous monitoring of every stage of production, including raw materials sourcing, assembly line operations, packaging, and transportation.

This way, any issues can be immediately detected and resolved before they become significant problems for customers.

By implementing robust quality control procedures, manufacturers can produce high-quality products consistently while minimizing waste and reducing costs associated with recalls or returns.

Quality Control Tools

As we dive deeper into the importance of quality control in manufacturing, it’s essential to understand the role that quality control tools play.

They act as a magnifying glass for defects and imperfections, enabling us to identify problems before they become more significant issues.

These tools help us optimize our costs by preventing recalls or rework expenses, which can be detrimental to any business.

Additionally, they ensure that our supply chain management runs smoothly and efficiently while maintaining high-quality standards.

By utilizing these tools, we can continuously improve our processes and products, providing better value to our customers while reducing waste and errors.

Quality Control In Different Industries

I’m interested in exploring the importance of quality control in manufacturing. To start, I’d like to discuss the process of implementing quality control and the various measures that can be taken. Additionally, I’d like to talk about the costs associated with quality control in order to understand how it affects different industries.

Implementing Quality Control

Have you ever purchased a product that didn’t meet your expectations?

Maybe it broke after just one use, or the parts didn’t fit together properly.

That’s why implementing quality control in manufacturing is so important.

Not only does it ensure that products are made to high standards, but it also saves time and money in the long run.

By catching defects early on, manufacturers can avoid costly reworks and delays in production.

Plus, customers will be more likely to trust and continue purchasing from companies with a reputation for producing reliable goods.

So let’s prioritize quality control in every industry and reap the benefits of cost efficiency and time management.

Quality Control Measures

Now that we know the importance of quality control in manufacturing, let’s delve deeper into the measures taken to ensure products meet high standards.

Quality control measures include risk mitigation and compliance monitoring to identify potential defects early on in the production process.

Risk mitigation involves identifying potential issues before they become problems, while compliance monitoring ensures that regulations are being followed throughout every step of production.

By implementing these measures, companies can save time and money by catching defects early on and avoid costly reworks.

With a focus on quality control measures, companies can produce reliable goods and maintain customer trust for years to come.

Quality Control Costs

Now, let’s talk about another aspect of quality control – the cost associated with it.

As a business owner or manager, you may be hesitant to invest in quality control measures because of the added expense.

However, conducting a cost benefit analysis can help determine if the benefits outweigh the costs.

Quality control costs involve various expenses such as employee training and equipment maintenance but these are necessary to mitigate risks and ensure compliance with regulations.

By investing in quality control measures early on, companies can avoid costly reworks down the line which could save both time and money in the long run.

It is essential to keep in mind that while implementing quality control measures has an upfront cost, it also provides significant returns by ensuring customer satisfaction and loyalty.

Quality Control In The Digital Age

Nowadays, quality control in manufacturing has evolved with the use of technology.

With AI compliance and data management systems, it is easier to detect defects or errors during the production process.

These tools help manufacturers save time and reduce costs by identifying potential problems before they cause bigger issues that require a recall.

In addition, digital quality control makes it possible to keep track of products from start to finish, ensuring consistency in output and customer satisfaction.

However, these advancements also come with challenges such as cybersecurity risks and adapting to new software technologies.

Despite this, embracing digital quality control can greatly improve efficiency and ultimately increase profits for businesses operating in the manufacturing industry.

Conclusion

In conclusion, I cannot stress enough the importance of quality control in manufacturing. It is a crucial aspect that ensures consistency and reliability of products. Without it, companies risk producing defective goods that can harm customers or damage their reputation.

Through my research, I have discovered that there are various types of quality control processes and tools available for manufacturers to use. From statistical process control to Six Sigma methodologies, each approach has its benefits depending on the industry’s needs.

As we continue to advance technologically, the demand for high-quality products will only increase. Therefore, implementing effective quality control measures across all industries is vital for success in today’s market.

So ask yourself: would you rather purchase a product from a manufacturer with rigorous quality controls or take your chances with one who does not prioritize it? The answer should be clear – invest in quality control to ensure customer satisfaction and long-term success.