The Reason For Micro Molding Suitable for Small Medical Products

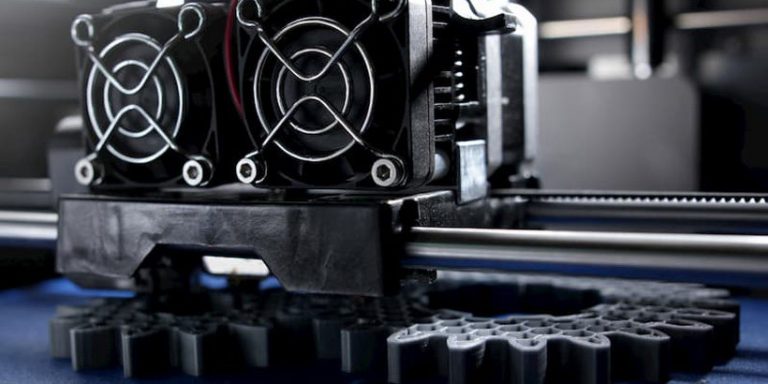

Micro molding is a specialized form of plastic injection molding for making components on a really tiny range. Just how tiny? Ended up components can easily consider less than 1 g and also determine smaller sized than 1 mm in cross-section.

Exactly how can this aid you? To understand the many advantages of micro molding for tiny plastic components, we need to initially look at exactly how this procedure differs from conventional plastic shot molding. We’ll be able to comprehend the applications it’s ideal matched for, especially in medication as well as relevant analysis as well as healthcare items.

Table of Contents

What Are The Benefits of a Micro Molding Machine?

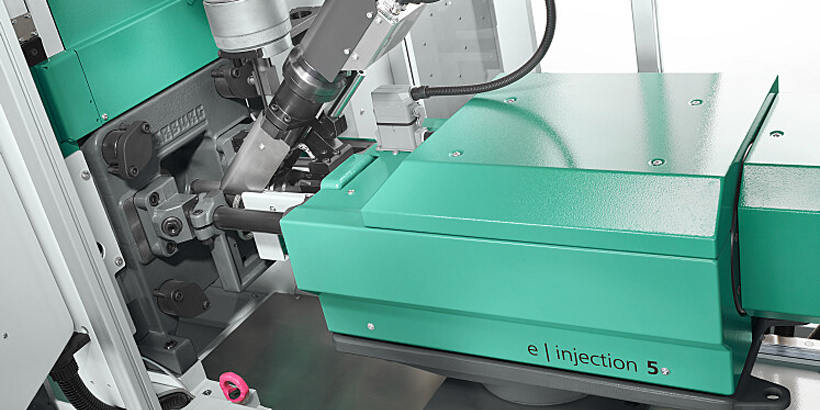

Small injection molding machines, such as our Babyplast 10/12, run at 10 lots of clamping force at most. For an item programmer, these machines stand for 5 unique benefits when making small components.

- Mold tools are much smaller as well as thus less costly, costing approximately 40% the rate of a full-sized tool.

- Micro molding eats much fewer resources. This consists of not only worldly utilized to make the component but also leftover resin in the gate as well as runner system as well as the barrel.

- Rapid changeovers are assisted by utilizing an online digital database that can hold one thousand unique job set-up parameters. And it’s also simpler and faster to flush old material out of the system to prepare the device for a different material.

- Warm jogger systems are made use of to specifically manage the temperature of the mold during production.

- Faster cycle times. Micro molding machines have short, compact barrels as well as gateways and also joggers are also of brief size.

Can Big Machines Make Small Components?

It’s technically feasible to utilize a huge maker to make really small parts. It’s not a very clever option.

Little components make use of the smaller mold, and also these have equally little caries, runners as well as gates. Larger equipment is tougher to manage precisely.

And using a large machine to make small components is a waste of sources because they have bigger barrels with a big quantity of liquified resin. Throughout one cycle, only a percentage of resin is utilized in each shot. The continuing to be material remains in the barrel, remaining hot for as well long. This creates the material to break down and also can wreck the component. Smaller makers avoid this problem since they have quicker cycle times as well as much shorter barrels.

Finally, bigger machines likewise consume much more electrical power, no matter the size of the finished part. These running costs are then passed along to the consumer, additional lowering process performance.

Dimension Matters

Plastic injection molding machines are rated by the securing pressure used to hold both halves of the mold and mildew together. Also, tiny traditional devices have a securing force of at the very least 50 lots. That’s the maximum amount of shot pressure such a machine can hold up against till the mold and mildew are compelled to open, which creates flashing and can damage the mold device. Drivers maintain the pressure below this limit, yet not much listed below. That’s because if the stress is minimized too low, there won’t be enough pressure to load the mold prior to the resin strengthens.

Are There Challenges for Micro Molding?

There are a few areas where micro-sized components position a greater obstacle for the molder.

- Tiny cavities with slim wall surfaces and little features are harder to the device right into the device steel. That’s why we utilize NAK80 or H13 polished stainless steel to make small mold devices. These steels have a great grain with a thick molecular structure so we can utilize our multi-axis CNC machines to make great attributes with high accuracy and also tight resistances.

- When micro molding contrasted to their full-sized counterparts, materials act in a different way. This is since materials experience high shear forces as they are compelled to load very little cavities quickly. Since sheer is carefully related to resin temperature and shot pressure, it is necessary to make use of devoted micro-machines that can be readjusted with fine gradations to attain ideal results.

Measuring Small Parts

Inevitably it’s not possible to make small parts dependably unless they can be measured reliably. That’s why we have actually progressed 3D scanners and coordinate measuring devices that we utilize at every critical action to constantly keep track of physical measurements. As well as naturally this very same cautious interest to information is made use of to make the mold tools.

What are Micro Parts Utilized For?

Among the fastest-growing markets for micro tools is the medical area. Some parts can be fairly tiny but relatively easy, while others hide wonderful complexity in an extremely tiny room.

What’s most important is that healthcare facilities, insurer and people are all curious about restricting as much as possible any type of invasive procedures inside the body. And also every person also intends to manage expenses. There is continuous stress to create new items on the small range that provide diagnostic and also therapeutic solutions that don’t call for surgical treatment. To do this, advanced applications combine passive enclosures with sophisticated electronics, sensing units as well as mechanical actuators to create a totally new class of health care tool.

Some devices are injected right into the bloodstream or positioned under the skin where they monitor many bodily functions. Various other sophisticated mini-machines might utilize microfluidic pumps to deliver tiny dosages of medicine. They can be made from bioabsorbable products that normally liquify inside the bloodstream, or immediately send signals to physicians or other caregivers should any kind of health problems fall outside a predetermined variety of values.

Is Micro Molding Right For Your Following Task?

The series of possible applications are frequently expanding and also is only implemented with innovative product solutions that support the latest item styles. Contact us to consult with one of our industry professionals to see whether innovative micro molding could be a remedy for your following product growth job.