The Role Of Mechanical Engineers In The Defense Industry

As a mechanical engineer, I have always been fascinated by the role that our profession plays in the defense industry. From designing and developing new weapons systems to improving existing ones, mechanical engineers are essential to the success of military operations across the globe.

In this article, we will explore some of the key ways that mechanical engineers contribute to national defense efforts.

One major area where mechanical engineers play an important role is in the design and development of vehicles used by military forces. Whether it’s tanks, helicopters or unmanned aerial vehicles (UAVs), these complex machines rely on advanced engineering principles to function at peak performance levels.

Mechanical engineers work closely with other specialists such as electrical and software engineers to ensure that every aspect of these vehicles meets stringent safety and reliability standards while also providing optimal functionality for soldiers in combat situations.

Design And Development Of Weapons Systems

Hey there! As a mechanical engineer in the defense industry, my primary responsibility is to design and develop advanced weapons systems that are capable of meeting the ever-changing needs of our military.

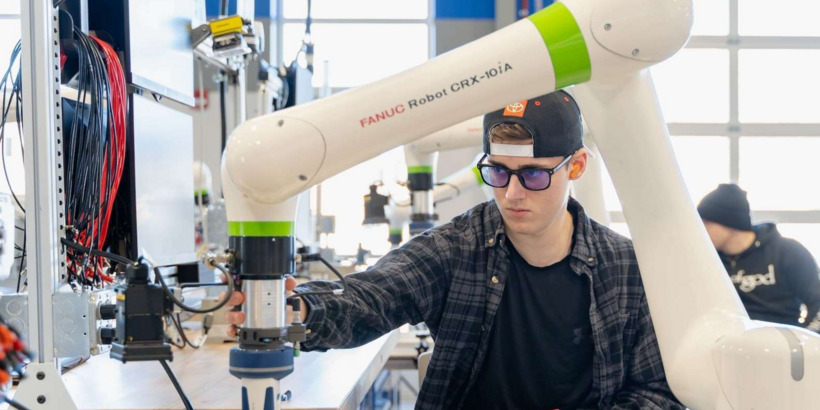

In order to accomplish this task, I rely heavily on cutting-edge technologies such as advanced robotics and simulation modeling. These tools help me to create highly accurate models of proposed designs which can be tested and refined before being built.

This allows us to identify potential issues early on in the development process, saving both time and money while ensuring that our products meet or exceed all necessary requirements. Ultimately, my goal is to provide our troops with the best possible equipment so they can carry out their missions effectively and return home safely.

Vehicle Design And Development

Now, let’s dive into the specific area of vehicle design and development within the defense industry.

As a mechanical engineer working in this field, my role is crucial in ensuring that vehicles are designed to meet the rigorous demands of combat situations while also maintaining optimal performance.

One key aspect of this involves automation integration, which allows for various systems to work together seamlessly and efficiently.

Additionally, robotics deployment has become increasingly prevalent in vehicle design, allowing for safer operations and increased capabilities on the battlefield.

Overall, as a mechanical engineer in vehicle design and development for defense purposes, I am responsible for creating innovative solutions that not only meet but exceed expectations in terms of functionality, reliability, and safety.

Prototyping And Testing

Moving forward, let’s delve into the exciting world of prototyping and testing.

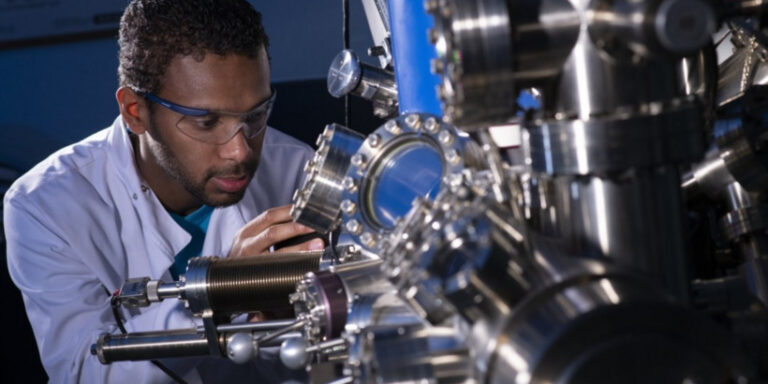

This is where we take ideas and concepts from simulations models to tangible objects that can be tested for their effectiveness.

Prototyping allows us to bring our designs to life through 3D printing, which creates physical versions of our digital designs in a matter of hours.

Testing then ensures that these prototypes meet strict requirements before they are deemed ready for production.

Through this process, mechanical engineers play a vital role in ensuring that every component meets the highest standards of quality and reliability, making sure that everything runs smoothly when it matters most.

Manufacturing And Maintenance

In the previous section, we discussed prototyping and testing in mechanical engineering for defense industry. Now let’s move on to manufacturing and maintenance.

As a mechanical engineer working in this field, it is essential to optimize processes while keeping costs in mind. Cost optimization involves using efficient methods for production without compromising quality. Process optimization refers to streamlining operations by identifying bottlenecks and finding solutions to eliminate them.

Manufacturing can involve complex systems that require attention to detail, precision, and safety precautions. In addition, maintaining equipment is equally critical as it ensures smooth operation of machinery and reduces downtime.

By implementing cost-effective measures and optimizing processes during manufacturing and maintenance, mechanical engineers can increase productivity while minimizing expenses for their clients.

Quality Control And Assurance

When it comes to quality control and assurance in the defense industry, mechanical engineers play a crucial role.

This involves ensuring that all products meet rigorous standards of safety, reliability, and performance while also keeping cost optimization in mind.

By harnessing data analysis techniques, we can identify areas where improvements can be made and streamline processes for greater efficiency.

As part of this process, we work closely with other members of the team to ensure seamless integration between different departments and technologies.

Ultimately, our aim is to deliver high-quality solutions that meet the needs of our clients while maintaining strict adherence to regulatory guidelines.

Research And Development

Research and development is like a compass, guiding us towards the future of mechanical engineering in the defense industry.

As a mechanical engineer, I have witnessed firsthand how computing simulations have revolutionized our ability to design and test new systems before they are physically built. This has allowed us to save time and resources, while also improving accuracy and safety.

Additionally, robotics automation has become an increasingly important tool for research and development in the defense industry. By using robots to perform dangerous or repetitive tasks, we can reduce human error and ensure greater efficiency in our processes.

Through continued investment in these areas, we can push the boundaries of what is possible and stay ahead of emerging threats to national security without putting human lives at risk.

Training And Education

When it comes to pursuing a career as a mechanical engineer in the defense industry, training and education are crucial components.

To excel in this field, individuals must have a strong foundation in math and science, which is typically obtained through undergraduate studies in engineering. However, many employers also require advanced degrees or specialized certifications for certain job opportunities within the industry.

It’s important to note that there are various career paths available for mechanical engineers in defense – from designing military vehicles to developing weapons systems.

With proper training and education under your belt, you’ll be well-equipped to pursue these exciting job opportunities and make valuable contributions to national security efforts.

Conclusion

In conclusion, as a mechanical engineer working in the defense industry, I can confidently say that our role is vital and multifaceted. We are involved in every step of the process from design to maintenance, ensuring that weapons systems and vehicles meet high standards of performance and reliability.

One of the most exciting aspects of being a mechanical engineer in this field is the opportunity to work on cutting-edge technology. From futuristic weapon concepts to advanced vehicle designs, we are at the forefront of innovation and pushing boundaries.

But with great power comes great responsibility, and we take our roles very seriously when it comes to quality control and assurance. Our attention to detail ensures that each piece of equipment meets rigorous safety standards before it ever sees use on the battlefield.

And ultimately, knowing that our work helps keep soldiers safe brings a sense of pride like no other.

Overall, being part of such an important industry is truly awe-inspiring. As engineers, we have the ability to shape history by contributing to national security efforts through research, testing and production. It’s not just about designing cool gadgets or machines – it’s about making sure those tools help protect people from harm. Working in this sector has given me immense satisfaction beyond compare!