The Ultimate Guide to Drilling Machine

Comparable to lathes, drilling machines are additionally among the most typical device devices utilized in the factory. As a functional device, the drill press mostly for piercing openings as well as a lot of other operations with correct devices. Below we’ll speak about the drilling device definition, parts and also kinds, functions and also uses.

What is a Drilling Machine?

A drilling machine, likewise called a drill press, is an effective tool utilized to reduce a round opening into or via steel, plastic, wood, or other strong materials via turning as well as advancing rotating drill little bits into a workpiece. This exploration reducing device is kept in the drill press by a chuck and fed right into the operate at variable speeds. The rate and feed ought to be established correctly as well as a coolant requires to be offered the wanted to end up component.

The drilling machine can not just be applied in the exploration process, but also beneficial for many various other machining procedures. There are numerous operations that can be carried out on a boring device, such as aeroplane exploration, step boring, core boring, boring, counterboring, reaming, countersinking, area encountering, tapping, as well as trepanning.

Drilling Machine Components as well as Functions

An exploration machine is generally composed of several or all of the adhering to parts.

- Base: usually bolted with the ground to support the weight of the drilling device.

- Column: situated on one side of the base, can carry the tons of the arm and also drill head, with a moving table placed on it.

- Arm: at the top of the column, carries the drill head as well as the housing of the driving system.

- Drilled: placed on one side of the arm, consists of a feed as well as the driving mechanism. It can glide up and down.

- Worktable: mounted on the column, can relocate vertically as well as flat.

- Feed system: hand as well as automatic feed by an electric motor.

- Spindle: holds the drill or reducing device and rotates in a fixed placement in a sleeve.

- Chuck: located on the spindle, holds the drill jig.

- Electric Motor

Kinds of Drilling Machines and Their Applications

Below are some different sorts of boring devices with their construction, qualities, and also uses.

- Radial drilling machine: generally for piercing large and also hefty workspaces, the table can be gotten used to match different heights. It enables the driver to make the pin directly over the work surface as opposed to relocate the part to the device, as well as likewise efficient in producing angular or intersecting keeps in one configuration.

- Upright drilling machine: larger and also stronger than delicate drilling machine, developed for dealing with a tool to large-sized openings.

- Sensitive drilling machine (Bench drilling machine): excellent for generating small holes at broadband, normally consists of a base, worktable, pin, drill head, driving mechanism and column. The work is started from the drill fed into the piece by hand.

- Portable drilling machine (Hand drilling machine): generally small in size as well as consists of a global electric motor, made use of for drilling openings on the rocks or any type of stiff surface area, ideal for any area. The piece to be drilled is kept in a vice.

- Gang drilling machine: can be made use of for exploration, reaming, counterboring as well as tapping, just require to relocate the device back and forth.

- Numerous spindle drilling machine: with numerous pins, ideal for piercing a huge amount of holes into a component and also boring the same holes on similar workpieces.

- Deep mole drilling machine: the unique kind that is made to drill deep openings in the connecting rods, pins and also others, with high reducing speed and also much less feed.

- Turret kind drilling machine: furnished with a number of boring heads installed on a turret, the tool can be quickly indexed into placement.

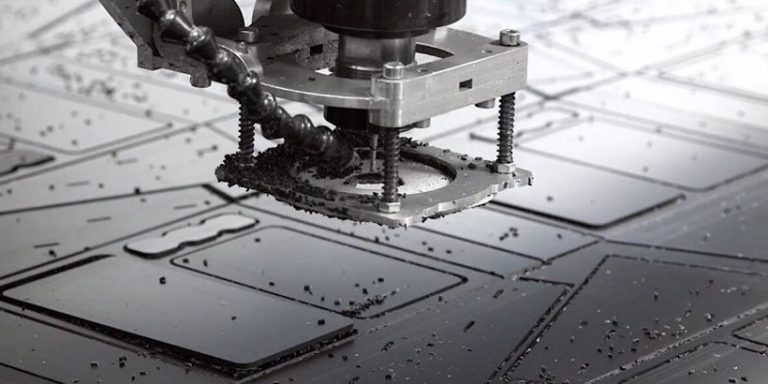

- CNC drilling machine: computer system mathematical control drilling machine can automatically change tooling with a turret or automated tool changer. The program controls the rates, feeds and table placement.

- Micro drill press: exceptionally exact, high pin speed, made use of to deal with really tiny or tiny components.