TOP 5 FAQs for beginners in CNC Machining

Exactly how to start with CNC is a typically asked concern for beginners in the market, you can browse some specialist sites, discussion forums, and business. Right here we’ll speak about the CNC basics for beginners covering FAQs like what machine you need to get, what little bits need to you get, the meaning and working of the CNC system, and also extra.

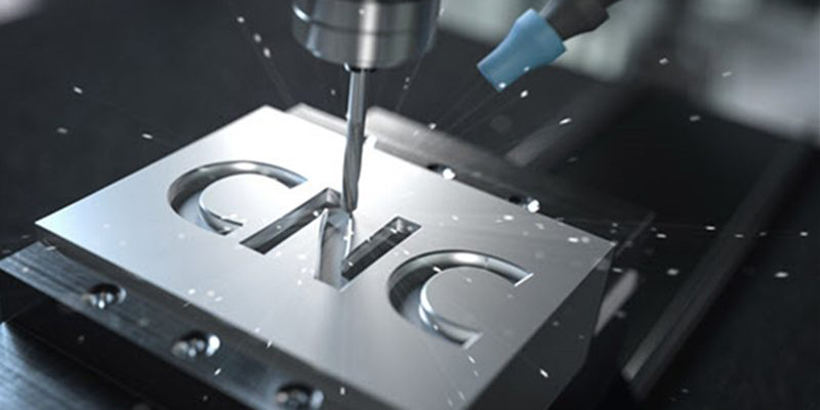

What is CNC and also CNC System?

CNC stands for Computer system Numerical Control, the mill or maker used for CNC machining services can be told what to do by a computer system rather than diddling around with a lot of handwheels. The CNC system consists of three major components: machine, the computer system (controller), and software. The controller includes both the computer as well as a program. Utilizing the little interface, you can inform the maker to do something, like mill out a pocket or take on a part or pierce basic patterns.

The Elements as well as Working of CNC Machine

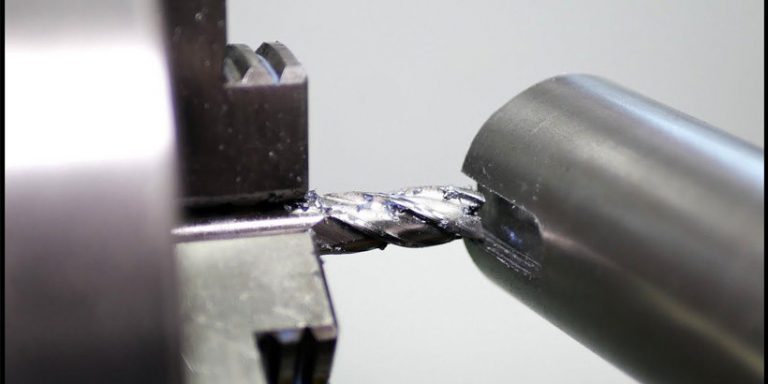

The machine, such as a mill, has a rotating pin that can run different quantities of reducing devices consisting of fly cutters, drills, various end mills as well as even more. The spindle can move up and down along the z-axis, it also has a table that moves side to side along the x-axis, as well as front to back is the y-axis. The motion of these 3 axes is driven by little stepper electric motors which can be managed in little as well as exact increments. By combining X, Y as well as Z-axis activities at the same time extremely, complex parts can be produced with tolerances in the thousands of an inch array. There are diverse extra devices that can be applied to the maker, such as add-on to oil the equipment and also cool the components, you can additionally manage the tool owners without tightening and also loosening up the drawbar which holds the devices in the spindle by adding a pneumatically-driven gizmo, the rooms can be contributed to make certain coolant will not splash.

What Software program Should I Make use of?

CAD/CAM software is different from the controller, you need to have a different computer system where you do your CAD or CAM job. There are many CAD, CAM, and integrated CAD-CAM programs like Inventor, AutoCAD, Fusion 360, and so on, Fusion 360 is a preferred cloud-based, incorporated CAD, CAM, and also CAE program offered by Autodesk, it permits you to create widgets on your computer and also tell your CNC machine exactly just how to set about making whatever you designed. When presenting the CAD parts, many people can obtain the keynote of what it resembles, you can attract the little 3-dimensional image out of simple forms and also sort of constructing it into an extra difficult component. Right here is the advised ideal free CAD software application 2020 for CNC.

For the CAM part, once you have actually generated a design for something, you need to find out precisely which tools you’ll utilize, what materials it is made from, the precise measurements in geometry, the software program is clever about exactly how it does points, the means it works, you define the tool and after that inform the machine to crap out this opening or make below level, it will certainly determine a method to do it. Once you define a given task and also a tool, the software program will certainly get exactly how to achieve that narrow task, specify where the device will go, and also exactly how quickly, the outcome is the tool course. The CAM software application uses a procedure to generate G-code, which is a straightforward program language utilized by most CNC machines. Check out the g-codes as well as m-codes of the CNC machine for comprehending the guideline.

What CNC Machine Should I Acquire?

There are numerous options on the market, you ought to stick to a lot of your store kind. When you get your machine, you should take into consideration a lot of variables. As an example, the dimension or how big of a machine should you get? The suggestion is as huge as you can suit your shop, take into account just how much room you have to adjust the larger machine to your store. Additionally, the shape of a machine will additionally have an influence on the process.

What Demand to Acquire Before the Machine Gets There

Prior to getting a CNC milling machine, what tool bit to choose is necessary. When picking the end mills, a starter bit set is a simple and rapid remedy to get you began. You have lots of inexpensive options for the brand name. What can be found in the starter set? It may be going to be your quarter-inch flat end mill, as rotates, it’s taking all your things as well as forcing it to the top of your cut. When you start, you can use this to reduce pockets and also even more functions, but they can’t cut square edges as they are round, which you need to discover in design. Various other choices like an eighth-inch end mill, end mill with different shank dimensions. If you are posting likely to get a machine with a DEWALT router, these sizes are permitted to be utilized. For machining tiny parts and also in-depth kind cuts, really little bits should be picked. The majority of the starter sets will certainly come with the V little bits, including a 90-degree little bit and 60-degree bit. There are likewise cone-shaped type bits, these are normally going to be used for 3D carvings.